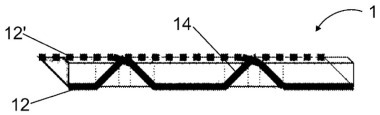

Welded lattice girders

The “Guideline on the Certification of Conformity of Welded Lattice Girders as Rigid Reinforcement” (official German title of the December 2017 draft: Richtlinie für die Übereinstimmungsbestätigung von geschweißten Gitterträgern als biegesteife Bewehrung; DIBt Section I 1, Concrete and Reinforced Concrete Construction) supersedes the previous guideline published in August 1993. It provides more specific guidance on the basis of national technical approvals granted for lattice girders and of DIN 488-6, Assessment of Conformity.

The new version of the guideline became necessary because DIN 488-6 refers to the manufacture of lattice girders at integrated wire processing facilities common at the time (in 2009) whilst providing only limited guidance with respect to steel users/concrete plants, which have become increasingly relevant over the past few years. Moreover, the previous specifications apply exclusively to lattice girders under predominantly static loading. Neither the 1993 guideline nor DIN 488-6 contain provisions pertaining to the fatigue strength of lattice girders under predominantly non-static loading.

All manufacturers of reinforcing steel products governed by DIN 488 and national technical approvals with reference to DIN 488 are subject to the so-called “release assessment”, which means that any product may be released for use only after having passed the test of specified characteristics as part of the internal production control scheme. The 2017 guideline expressly describes this approach under Item 3.2 (3), “Internal Production Control”: “The integration of lattice girders or of precast elements manufactured therefrom into a building or structure without prior testing and positive assessment of test results is not permitted.” The individual requirements for lattice girder producers are summarized in the following sections:

Factory label

Both the wire manufacturer label (producer of the input material for lattice girders = factory label) and the label of the lattice girder producer (= welding contractor label) must be affixed (no change compared to the previous version).

Internal production control

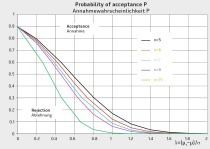

On the basis of previous experience, the lattice girder guideline specifies a testing unit that deviates from DIN 488-6 to be able to ensure sufficient production safety and reliability even for annual outputs of up to 2,400 t. However, to verify the shear force at welded joints, at least one testing unit must be checked upon each changeover to another type of girder, or at least per each working day. This test is performed by “competent testing staff” in accordance with the initial testing provisions (see below) using “appropriate, calibrated test rigs (for example a tensile test machine)” at the manufacturing facility.

Initial testing

This section specifies the general details for initial testing as well as for assessing manufacturing conditions and for ensuring internal production quality control and checking product characteristics, including the requirement of “appropriate, calibrated test rigs … and competent staff …” at the manufacturing facility.

Third-party inspection and quality control

The guideline also includes provisions on inspection and quality control reporting, including individual and annual reports specifying production outputs, production downtime, rebar combinations, number of factory visits, and complaints, as well as corrective actions to be implemented in the event of non-compliance with requirements.

DIN 488 applies to the execution of tests and assessment of test results. The annex to the guideline includes rules for initial testing, internal production control and third-party inspection and quality control to determine the fatigue strength of lattice girders under predominantly non-static loading. According to these provisions, both exposed welded joints and welded joints embedded in concrete cubes must be checked (the guideline contains detailed information on tests and related analyses).

Approvals and certificates of conformity

Any extension of the validity of a certificate of conformity upon expiry of the relevant approval (in the same way as for an extension of the approval itself) requires the inspection and quality control body to compile a summary report stating that the results meet the requirements specified in the relevant approval and in the guideline.

The draft guideline will be discussed on 1 February 2018 at Deutsches Institut für Bautechnik, Berlin. The subsequent presentation to be delivered on 21 February 2018 will incorporate the decisions adopted on the consultation date referred to above.