Ultra-high-performance concretes using standard

cements without concrete additives

The wide variety of different designations given to high-performance concretes, such as UHPC, UHPFRC, DFRCC, SHCC, RPC etc., reminds to biblical language confusion. Their approval procedures are no less complex due to the lack of applicable guidelines.

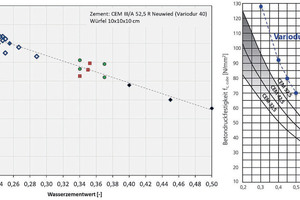

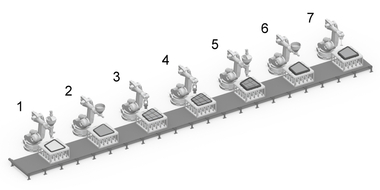

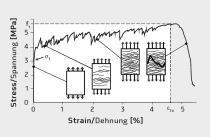

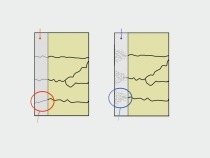

Yet, they offer major advantages: the highly dense structure of high-performance concretes significantly improves compressive and flexural strengths, increases resistance to chemical and mechanical attack. In the final analysis, it leads to improved performance characteristics and increased durability. Paired with sometimes significant reductions in cross section, this type of construction, which is more expensive in production than standard concrete, usually pays for itself within a few years. Upon publication of the DAfStb guideline “UHFB” on ultra-high-performance concretes, the new C130/145, C150/165 and C175/190 strength classes will be included in the revised edition of the concrete standards, and the use of ultra-high-performance concretes can be implemented on a large scale in building practice without the need for extensive approval tests. Solutions using standard cements from Dyckerhoff on the basis of state-of-the-art cement technology do not require pozzolanic additives such as silica fume, and can be implemented using standard aggregates and standard concrete mixing technology. The standard cements for high-performance concretes known under the product name of Variodur are produced at the Neuwied cement plant in complex grinding, classifying and mixing processes. The state-of-the-art production process has optimized particle size distribution of the Variodur cements for this type of application. It is therefore possible to produce ultra-high-performance concretes without using multi-component binder mixtures or binder compounds outside of DIN EN 197-1.