UHPC in machine construction

Machine beds and frames are primarily manufactured from welded steel components, gray cast iron, or natural hard stone. Since the 1980s, epoxy-resin-bound polymer concrete and mineral casting materials have additionally become established, due to their technical and cost advantages. For about six years, ultra-high-performance concrete (UHPC) has been successfully used for the manufacture of metal-processing machine tools. Machine construction in Germany, with consumption of several thousand tons of this material yearly, is the largest sales market for high-strength and ultra-high-strength concrete. Concretes based on the binder Nanodur Compound from Dyckerhoff GmbH are global market leaders in this area. Machine components made with this binder are manufactured in several plants in Germany as well as in Switzerland, the Czech Republic and China.

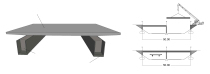

The machine bed is that part of such machines onto which all movable components of the milling or grinding machine are installed. It is delivered as an integral part of the machine and is distinguished from the machine foundation, which is part of the building. Essential advantages of such concrete use – apart from vibration absorption and thermal inertia – include short delivery times and a favorable price for forms and components. The challenge for the precast plant is to guarantee absolute absence of cracks, both during manufacture and for the entire lifetime of the machine. The form itself directly ensures tolerances of up to 0.1 mm. Surface flatness and parallelism of up to 5/1000 mm over a length of 4.5 m are achieved by subsequent milling and grinding.