The art of concrete: Beauty from within and without thanks to OTE Surface Protection

On the way to a better future – OTE Surface Protection

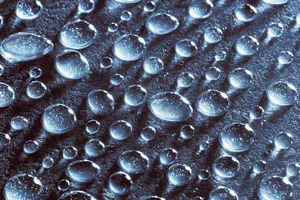

Certainly, as far as concrete is concerned, beauty does not come to mind spontaneously. But on a closer look, the perspective is changing. Because the proper surface protection ensures that concrete radiates beauty, unfolding and preserving its very unique aesthetics.

The demands have constantly increased in the last few years. Nowadays, customers are much better informed and will accept no compromise: Contemporary concrete products are all-rounders. They not only need to meet functional aspects such as strength, water absorption and frost resistance, but also ensure the high expectations on cleanability and freedom from efflorescence along with durable aesthetics.

Being beautiful is good, but beautiful in perpetuity is even better

In comparison to the past, today‘s final customers identify more strongly than ever with the concrete products of their choice. Concrete shows its „face“ and places emphases. Concrete is talking to us and requires attention. Not only home and garden express the individuality of the owner, but concrete paving blocks also demonstrate taste – or maybe not. All the more important is to make the right choice of concrete products and kind of surface production. But what should the consumer or the architect issuing the invitation to tender take into account? Which assessment criteria are informative?

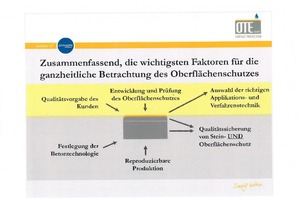

Hocus-pocus is not helpful here, but tangible answers are needed. Omnicon takes account of customer requests and supplies high-end products exclusively, which are developed and tested in the own company. Even though, the one or other development may take quite some time. For good reason, this does not take place on site at the customer, but research, improvement, and tests of his surface protection are conducted together with the customer in our laboratories, using our plants and equipment. In this way, we create a „total work of art“ made of concrete.

This approach allows for a repeatable and holistic production of a surface protection which evidently leads to fewer complaints.

Imprecise criteria are as nails made of rubber

According to the manufacturer, there are some suppliers who promise a lot and keep little, or who impose the customer with a high risk instead of developing an appropriate solution.

According to this, many manufacturers do not submit a detailed description of the concrete products but refer to unspecified properties such as „free from graffiti and chewing gum“, „resistant to de-icing chemicals“, or „stain-resistant“. Such vague phrasings, however, conceal potential real differences in quality. There are even other and much better ways:

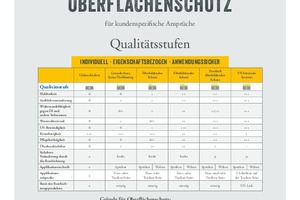

OTE Surface Protection GmbH, a subsidiary company of the Omnicon Group, has extensively dealt with the assessment criteria and developed a system of quality levels, classifying coated concrete products in an informative way. The basis of this system is a test catalog based on standard tests and test methods developed internally. In this respect, OTE is focusing on a holistic consideration of the production systems as well as finishing systems – because this is the only way how high-quality surface protection works. At first, the concrete is optimized and tested from within. By means of an appropriate surface protection and the right application technique, OTE then ensures that the concrete will develop its entire beauty – from within and without.

The test method in short: How much water fits in a concrete block?

For testing the total water absorption, a concrete block specimen is placed into a water bath for three days and is dried afterward. How much water the block has absorbed is determined by weighing, both after having been in the water bath and again after drying. This test indicates the diffusion pressure which plays an important role in the durability of a coating. The test method examines whether the concrete of the customer features a sufficient quality, or whether an additive can optimize the same. The test equipment of OAVERtec, determining the porosity and the density, plays an important role here. The respective application technique is adapted on the basis of the results.

Sunbathing for two thousand hours

The Xenotest indicates the resistance to fading and destruction of the pigments in a coating caused by sunlight. The coated surface of a test specimen is exposed to a special ultraviolet light and subjected to rain. Test duration is at least 2,000 hours.

Frosty times or thaw – or both in cycles?

The freeze-thaw test examines the behavior of concrete surfaces under freeze-thaw conditions. Does the coating peel off due to the action of deicing chemicals and under the condition of alternating temperatures (freeze-thaw) – and if so, when and how much?

Ketchup, shoe polish or red wine?

In the soiling test, the use of paving blocks is simulated under realistic conditions. Staining substances such as ketchup, shoe polish, oil and red wine are applied to the blocks. They are removed with the aid of household cleaning agent after an exposure time of 16 hours at 20 degrees Celsius. The results indicate the degree of resistance of the surface to soiling.

150 bar at a distance of 15 cm

In the high-pressure cleaning test, the surfaces of the test specimens are subjected with a high-pressure cleaner from a distance of 15 cm and the coating is then examined for damages such as spalling. This test can be combined with the soiling test in order to achieve the most realistic conditions possible.

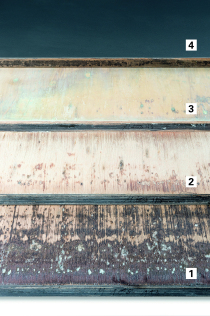

Even concrete can show a face – actually 5 faces

Once all tests have been completed, an assessment is carried out next and finally the classification into one of the five quality levels specified takes place. QL 1 (quality level 1, basic protection, no film forming) represents the lowest level and QL 5 (UV hardening systems) the highest level (see quality level table).

Advantages of the 5-level system:

The quality level system provides manufacturers of paving blocks with a professional and reliable orientation for the development or optimization of coated products.

The sales department gets a useful argumentation basis in selling. Fuzziness is a thing of the past, now there is a system.

The final customer will be satisfied sustainably as he gets the right quality product. Because surface protection is a matter for the professional, preventing customer complaints through the right selection right from the beginning.

Beautiful concrete is a sustainable work of art – with system

The requirements on concrete paving blocks have grown enormously. The aspects of durability and sustainability are playing an ever greater role as well.

The competent work of the Omnicon Group‘s specialists in close cooperation with the customers enables them to create a paving block that meets today‘s requirements in the highest quality – and this even for a long period. Because the clients and architects also work much more in the long run than previously and they want to create architectural works of art, that will yet inspire by functionality and design for many years to come.

The close cooperation with the customers, the joint research and development activities with national and international universities as well as the own great motivation for making something good even better, encourages the employees of the Omnicon Group to create new works of art unfolding their beauty in an interplay with the surrounding environment.

Essential recommendation for concrete product manufacturers

Concrete product manufacturers should directly contact the application engineers of OTE when it comes to the development or optimization of a coated product. Together it is possible to define exact objectives, to optimize existing recipes, if required, and to adapt and test application methods so as to get a perfectly adjusted surface protection. Or as the specialists of OTE put it: a concrete that shows its beauty from within and without.

CONTACT

Omnicon GmbH

Heideland 20

24976 Flensburg-Handewitt/Germany

+49 461 48071-11

Omnicon A/S

Stødagervej 6

6400 Sønderborg/Denmark

+49 461 48071-11