The “Green Wave” – a noise barrier connects culture with nature

In an out-of-the-ordinary endeavor, a well-known brewery installed a noise barrier around its headquarters to prevent noise from being emitted into its surroundings, rather than the other way around. The wall surface was prepared for attaching green moss covers to soften its hermetically closed appearance.

The community of Krombach is situated in a prime location within the Krombach Valley. It is characterized by three inseparable features, namely its natural surroundings, the history of the place, and the Krombacher brewery. Taken together, they determine the place’s overall identity whilst influencing each other. Nature is abundantly visible all across the place, including streams flowing through it like arteries, green meadows and pastures, and beautiful vistas of forest-covered mountain slopes. South of the village, the Krombach stream flows through the area in east-west direction.

Low environmental impact

The addition of a new high-bay warehouse to the Krombacher brewery premises required the design and construction of a noise barrier as well as realignment of the Krombach stream course. These works were very challenging but also provided the opportunity to establish a new, sustainable image of the Krombacher brewery within the context of the place. Siegen-based construction contractor Otto Quast was commissioned with producing and installing this exceedingly sophisticated noise barrier.

Landscape architect Andreas Kipar oversaw the design of this project. He had to harmonize the design of the ten to twelve meter high wall and the extensive brewery facilities behind it with the surrounding green landscape marked by hills and the Krombach stream flowing nearby. Ever since its establishment, the brewery has used water from regional rock sources for the beer-brewing process. For this reason, the business aims to implement a sustainable, environmentally friendly, and resource-saving production process whilst respecting and preserving natural habitats.

The noise barrier was necessary from an engineering point of view; it was carefully aligned with its natural environs and interpreted as a “landscaped” wall. The shapes created by the ascending carbonic acid bubbles add a second, similarly curved membrane to its initially purely functional design. This is why the wall was given a waved shape and a surface texture to lend a more lightweight appearance to the structure.

Added greenery

The Krombach islands are a crucial element of the place’s identity; they were projected onto the noise barrier’s second plane. Many beer lovers will recognize these islands from Krombacher TV ads – their shapes are symbolized by moss applied to the vertically sloping wall.

As a basic beer ingredient, hops is also an essential component of the noise barrier design. It is characterized by its strong growth, attractive flowers, and agreeable scent. The wall includes sloping sections reminiscent of actual hop growing.

Its greenery adds environmental value to the structure: the moss was sprayed onto the formliners as a mixture of cellulose, natural adhesive, earth, and small pieces of plants. Once it has taken root, it will function as a fine filter absorbing the exhaust gases inevitably generated at the empties warehouse. According to Kipar, one square meter of moss will filter as much as 17 fully-grown trees do. Thus, the filtering capacity of the 270 square meters of moss applied to the wall is equivalent to that of over 4,000 trees.

Thanks to its added environmental value, the noise barrier does justice to the brewery’s dedication to sustainability and environmental awareness. This vertical landscape will change with the seasons, offering residents an ever-changing view that contributes to enhancing a green lifestyle.

Rehabilitation of the Krombach

The redesign of the Krombach responds to key features of the surrounding landscape. The stream is embedded into the remodeled, gently sloped terrain reminiscent of a riparian landscape. Strips of flowering wild perennials replicate the curved wall design along the banks of the Krombach. Groups of trees and shrubs typical of a riparian setting emphasize the vertical plane and establish a link between the road space and the stream. Rehabilitation and opening-up of the Krombach adds value to the entrance to the village at Hagener Strasse, and creates an area that is much more inviting than before.

The waved shape of the noise barrier blends in harmoniously with, and reflects, its natural surroundings typical of the place, thus establishing a connection between culture and nature. From an engineering viewpoint, the noise barrier extends to a total length of 185 m. It is 6 to 10 m high and up to 1.90 m thick. In some places, it shows a projection of up to 2.40 m from its central axis. The wall comprises 63 columns, 93 bases, and 78 curved and 103 planar wall panels with formliners. The wall is supported on a system of 142 Quast displacement piles whose lengths add up to a total of 1,100 m. These piles provide the support for pile head foundations with integrated sleeves in which the up to 11 m long columns are embedded.

Wall surfaces should be exceedingly rough and exhibit various undercut patterns to be covered with moss and a range of other plants. The Cheyenne formliner supplied by Reckli proved to be particularly suitable for this purpose; it imprints a rock structure typical of the French Alps onto the concrete.

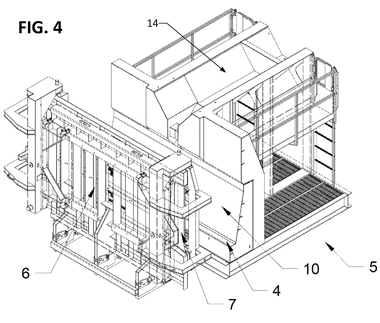

Production

For Otto Quast, the noise barrier project posed the big challenge of having to handle as many as 274 different elements with a deflection of up to 1.5 m in the vertical plane. The geometric panels were produced in dimensions of up to 3.3 m × 4.5 m. Thus, a form had to be constructed that enabled three-dimensional adjustment in all directions. Its support frame was composed of wooden studs that mirrored the specified contours of the individual noise barrier panels. The formliner got a much thicker design than usual, and stud spacing was minutely adjusted so as to eliminate the need for an additional form layer.

The above main formwork components were carefully aligned with each other, and thus greatly facilitated the creation of the waved shape. Custom CNC-milled lateral form pieces were attached to the formliners to replicate the contours of the individual wall panels.

The concrete specified for this project posed yet another major challenge because it was to exhibit sufficient stability and strength to overcome the great differences in height during the concreting process whilst preventing it from flowing downward in the direction of the form base. Likewise, the concrete should enable easy consolidation to create pore-free surfaces.

Installation

Installation of the twisted and skewed wall panels was just as demanding. For assembly purposes, the varying centers of gravity of the individual panels had to be aligned depending on their respective inclination. Thanks to the high dimensional accuracy and quality of the elements, the Otto Quast construction gang managed to complete the assembly process after seven weeks, installing up to 37 panels per day.

The end result is a noise barrier compliant with applicable noise regulations that will ultimately blend in with the magnificent green landscape with its gently rolling hills and the stream course.