Sustainable and ecological ultra-high-performance concretes – contradiction or perspective?

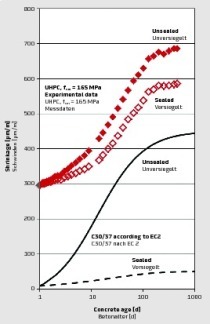

Conservation of resources and sustainability are the current global objectives. Improvement of the CO2 balances of cements and concretes are in the focus of scientific studies. Increasing industrialization results worldwide in increasing demand for cement for building more sustainable and efficient infrastructure as structures and residential buildings. Ultra-high-performance concrete (UHPC) enables erection of very efficient and durable structures (Fig.). Ultra-high-performance concretes, owing to their high cement content, however, when taking into account their CO2 balance, are seemingly not environmentally friendly. But longer service life and lower repair costs put this into perspective.

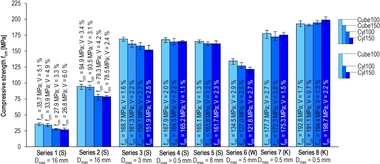

Calcinated clays are currently being investigated worldwide for their suitability as clinker substitute, which, mixed with limestone flour as LC², are available on the Asian and Latin American markets. This alternative binder mix has been used in the manufacture of UHPC with the objective of more environmentally friendly production of UHPC with an enhanced CO2 balance. For this reason, the UHPC cement was substituted by 10 to 50 % of LC². After 28 days, the reference UHPC achieved a compressive strength of 205 N/mm².

Substitution of 40 % of the reference binder by LC² reduced the compressive strength of the UHPC by approx. 25 %, to 156 N/mm², so that, based on the definition of the DafStb, a UHPC can still be manufactured. Here, however, only the 28-day compressive strength was considered. The current state of knowledge, however, is that the calcinated clays react significantly slower than do Portland cements: with the result that a further increase in strength can be expected over time.

Calcinated clays as cement substitute in UHPC result in a reduction of strength; but the concretes manufactured with them are still high-performance concretes and can be used as such. But their CO2 balance is clearly more positive and their optimized structural composition makes them durable.