Strategies to minimize restraintstresses in conventional reinforced-concrete structures and in particular in water-impermeable structures

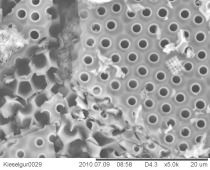

The main function of concrete curing is to minimize premature evaporation of water across the concrete surface. Concrete can achieve the desired strength and durability characteristics only if a sufficient amount of water is available in the concrete fringe zone for the ongoing hydration processes. Another function of curing is to avoid larger temperature differences in the concrete cross-section to counteract potential crack formation.

The aim of the new Guide to Good Practice on Concrete Curing (March 2019 edition) is to provide assistance to building contractors to select suitable curing measures and to determine the required duration of the concrete curing process depending on the functions and goals to be achieved by curing and within the scope of Eurocode 2 or ZTV-ING (Zusätzliche Technische Vertragsbedingungen und Richtlinien für Ingenieurbauten; Additional Technical Terms of Contract and Guidelines for Engineering Structures). The information and recommendations included in the Code of Practice on Concrete Curing are additionally intended to achieve a comprehensible documentation of the curing process as defined by DIN EN 13670 and DIN 1045-3.

The objective(s) of concrete curing listed below determine the kind and duration of the curing measure(s):

1. achieving sufficient strength and high durability (density) of the concrete fringe zone;

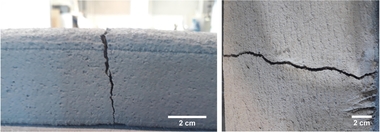

2. reducing the potential for cracks resulting from early shrinkage (plastic shrinkage);

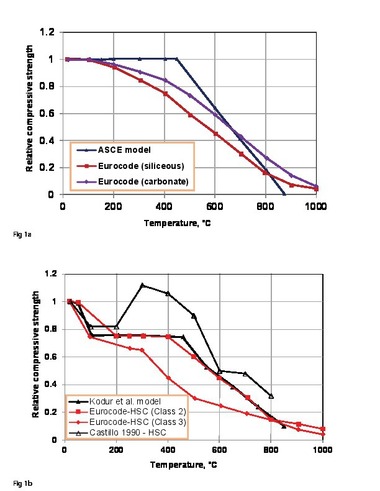

3. reducing the potential for cracks resulting from thermal stresses caused by strain resulting from:

a. development of hydration heat in the concrete; or

b. prevailing weather/ambient conditions in particular in the case of non-shuttered concrete surfaces;

4. meeting requirements placed on the look of exposed concrete surfaces.

DIN EN 13670 and DIN 1045-3 do not explicitly deal with measures for reducing the potential for cracks resulting from restraint strains caused by changes in temperature and any resulting stresses (objective 3), or with curing exposed concrete surfaces (objective 4).

The Code of Practice on Concrete Curing also includes detailed information on controlling heat dissipation, in particular in connection with implementing design principles relating to crack formation.