Simply Red – deep red in the cowshed

A farmer in the Bavarian city of Markt Beratzhausen in the rural district of Regensburg in Germany matched the color of his technical systems with the color of the construction material for his new cowshed. Both the milking robot and the concrete for the enclosure were colored in deep red.

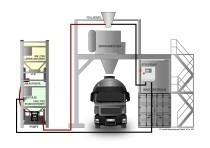

Before beginning with the construction of the new shed – 28 x 53 m in size and with a fully automatic milking system and free cow traffic – it was necessary to satisfy numerous regulations. The farmer Konrad Koller, also the project client, explained some of these regulations: “The corridors between the resting areas for the 75 cows were required to have a width of at least 5 m, a drinking trough, and a sufficiently large free-range area of 7.50 x 36 m.” The designed slatted floor required a special in-situ concrete liquid manure channels.

Red concrete

instead of tiled surfaces

In late June of 2015, as soon as all of the requirements had been complied with, construction began, even if the unusually hot summer made the work more difficult for the building contractor Meier Bau GmbH from Lupburg, Germany. “We had between 35 and 40°C the whole time,” said Koller. “The concrete mixers often arrived much earlier than scheduled, because all other customers had cancelled their orders due to the heat –but we carried on. The Meier Bau workers really took a lot of punishment.”

Especially great importance was placed on the surface of the exposed feeding table, although work had to progress at high speed due to the high temperatures. Casting was followed by troweling and then grinding of the fresh concrete. The Koller family also placed great importance on the appearance of the fully automatic milking parlor: “The enclosure of the milking barn was constructed of red concrete,” said Koller’s wife Michaela. “The alternative would have been tiles, which would have required gluing and pointing. Concrete, moreover, is much less sensitive than tiles. Based on these considerations, the decision was clear: concrete, but in a red that matched our Lely milking robot,” she explained.

Slatted floor

made of precast elements

Specialist consultant Hans Zeitler from Betotech Nabburg, was on location and found the matching red shade. To obtain a concrete surface as flat and smooth as possible, Betonplan panels were used as formwork. Afterward, the name “Lely” was cut out in mirror image, glued into the formwork, and after hardening highlighted with gray.

The slatted concrete floor and the steel-wood construction of the barn consists entirely of prefabricated parts, which were then simply and quickly assembled. Room for more cows has already been provided for. A storage area can be repurposed when needed.