Predicting concrete shrink-behavior

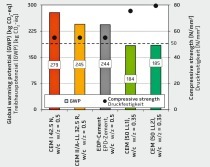

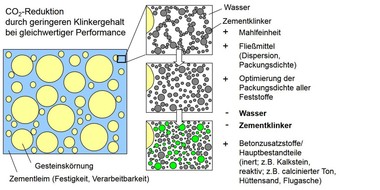

The cement industry generates about 6% of global CO2 emissions that are primarily caused by the production of Portland cement clinker. A reduction in the clinker content of cement and concrete and its substitution by increasingly adding limestone-based cements is found to be one of the most efficient approaches to reducing the greenhouse gas potential of concrete production. In a research project, concrete made of cement with 50 wt.-% of limestone and a reduced water-cement-ratio of 0.35 proved to exhibit sufficient properties in its fresh and hardened state whilst significantly lowering CO2 emissions by up to 25% compared to conventional concrete [1]. However, the deformation behavior of such concretes with high limestone content, particularly their long-term creep and shrinkage, was found to be significantly influenced by the type and quality of the limestone [1].

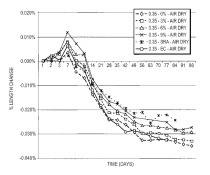

An in-depth experimental research study analyzed the drying shrinkage, autogenous shrinkage and carbonation shrinkage behavior of hardened cement paste and concrete made with cements that contained various types and proportions of limestone. It was found that the shrinkage of concretes with high limestone content strongly depended on the chemical-mineralogical properties of the limestone. The limestone’s alkali content and methylene blue value were identified as the most significant influential factors.

Based on the experimental findings and thermodynamic laws and mechanics of the porous materials, a multi-scale model was developed to predict the drying shrinkage of hardened cement paste and concrete as a function of the content and chemical-mineralogical properties of limestone. This model considers capillary and disjoining pressure as the main shrinkage mechanisms [2]. Furthermore, the suitability of the current DIN EN 1992-1-1 standard for predicting the shrinkage of concretes with high limestone content was evaluated, and a proposal was made to modify the design model for concrete accordingly in order to consider the content and chemical-mineralogical properties of limestone.