Precast concrete specialist with experience and effectiveness

More than 110 years after the foundation, the GLÖCKLE group of companies presents itself as a partner for holistic solutions in the fields of construction and real estate. The building contractor GLÖCKLE Montagebau GmbH with its own two precast plants is supplying the precast elements for numerous projects in the fields of building construction and civil engineering. Not least thanks to special plant equipment – a 60m long casting bed for prestressed concrete girders and adjustable molds for columns with footing –, the company based in Lower Franconia can supply, what only a few others can.

The construction industry is booming in Germany. For 2019, the Federation of the German Construction Industry (HDB - Hauptverband der Deutschen Bauindustrie) and the Central Association of the German Construction Trade (ZDB - Zentralverband des Deutschen Baugewerbes) again forecast a nominal sales increase in the main construction trades of about 6% compared to the previous year – the plus applies to all segments from residential construction (+ 5.5%, expected sales volume of 47 bn euros) to commercial construction (+ 6.0%, expected sales volume of 45.6 bn euros) through to public construction (+ 6%, expected sales volume of 35,3 bn euros).

The GLÖCKLE group of companies also benefits from the good economic situation (see page 55, GLÖCKLE – the company). The family-owned company, that celebrated its 110-year anniversary last summer, states annual revenues of about 120 million euros in the company‘s brochure issued in 2018.

At present, all five business units of the group of companies enjoy good capacity utilization. This also applies to the „prefabricated construction“ unit, comprising the group‘s two precast concrete plants located in Schwebheim, in the Lower Franconia region in the German Federal State of Bavaria, and in Meiningen, in the Federal State of Thuringia.

Flat, bar-shaped and special precast elements

Quality instead of quantity, that already starts in planning at GLÖCKLE . „We put less emphasis on high cubic meter figures, but we put emphasis on the result. Because only the results allow investments later,“ Dipl.-Ing. Klaus Glöckle, stockholder and managing director of the GLÖCKLE group of companies, describes the fundamental corporate philosophy.

At the Schwebheim location, which is presented to the BFT editor by Klaus Glöckle, Harald Läpple, general manager of prefabricated construction, and factory manager, Matthias Raschke, the flat, bar-shaped and special elements are manufactured in three factory halls for the building construction and civil engineering business units.

The flat elements, such as solid and sandwich walls, frost skirts and façade panels are manufactured on large production tables of Avermann. The unit weights of the flat elements can amount to up to 25 t. Timber formwork is used for elements with particularly sophisticated geometries and surfaces, such as façade elements (s. Fig. 3 and 4).

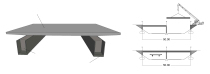

The bar-shaped elements manufactured by GLÖCKLE include prestressed concrete girders, beams as well as columns and columns with integrated footings. The columns can have a maximum length of 25 m, the footings a maximum size of 3 x 3 m. The maximum unit weight of bar-shaped elements normally amounts to up to 25 t, in exceptional cases even up to 40 t are possible.

60m long prestressed concrete casting bed

Two molds of Tecnocom and some other molds of another supplier are available for the production of columns with integrated footings. The in-house machine construction supplemented the column molds with adjustable devices integrally molding the footings.

A 60m long casting bed is available for the production of prestressed concrete girders in Schwebheim. The formwork for the girders came from Howal, the prestressing equipment from Paul, the German specialist in prestressed concrete. A maximum of 60 strands can be loaded with 100 kN each.

Of course, girders of 50 m or even 60 m length are unusual; the bed is rather divided and several girders are cast. „The longest girder which we have cast so far is 37.5 m long,“ Läpple emphazises.

Columns with integrated footings and large prestressed concrete girders likewise provide GLÖCKLE with a unique selling proposition in the market. „Very few direct competitors are in the position to offer comparable elements,“ states the general manager of prefabricated construction.

The special precast elements produced in Schwebheim include stairs, precast balcony elements, balustrades and loading bridges, for example. And the specialists are able to deliver other special precast elements on request.

From Milaneo to Reglermauer parking garage

The exemplary references, to which the two facilities of Bauunternehmung GLÖCKLE Montagebau GmbH have supplied precast elements, undoubtedly include the „Milaneo“ completed in 2014 – a three-story building complex in Stuttgart‘s city center, with a shopping center, featuring a sales floor of 43,000 m², as its core (s. Fig. 10).

GLÖCKLE Montagebau designed, produced and delivered the overall 1,283 girders for the building project.

Further exemplary references are the extension of the administration building as well as the area of incoming and outgoing deliveries of Roswitha Schum Logistik GmbH & Co. KG located in Dettelbach near Würzburg and the Reglermauer parking garage in the city center of Erfurt.

GLÖCKLE designed, manufactured, delivered and installed 838 precast concrete elements for the extension of the administration building as well as the area of incoming and outgoing deliveries of Roswitha Schum Logistik GmbH & Co. KG. The new building consists of a four-story precast reinforced-concrete structure. The floors are designed as TT slabs supplemented with in-situ concrete which are supported through prestressed beams resting on columns. The columns are partially designed with footings, as columns with socket and columns with Peikko connection. Sandwich elements are used for the façade in the area of the loading bridge. The companies own formwork system was used for the production of the loading bridges. The installation took place within only twelve weeks.

Growth prospects

The Reglermauer parking garage is a real eye-catcher. For one thing, this is due to the brightly shining façade, consisting of wavelike curved panels made of Dyckerhoff white cement; and, for another thing, it is due to the fact that the façade creates a visual counterpart to the darker natural stone façade of the Regler Church on the opposite side (s. page 52).

Bauunternehmung Glöcke Montagebau was awarded a contract for planning, manufacturing, delivering and installation of the 115 precast elements. The base plates of the façade exhibit the rock pattern of the textured formliner „Fichtelberg“ of Reckli. Formwork elements specifically manufactured for this purpose in the Netherlands were used for the production of the white waved façade panels.

„We are certainly in the position to run three or four major projects simultaneously. We are able to provide certain quantities of formwork and use them in production. This flexibility and our powerful prestressed concrete production make us a very effective medium-sized enterprise,“ states Dipl.-Ing. Klaus Glöcke, confidently looking into the future.