Pioneering mineral composite systems for precast

concrete construction

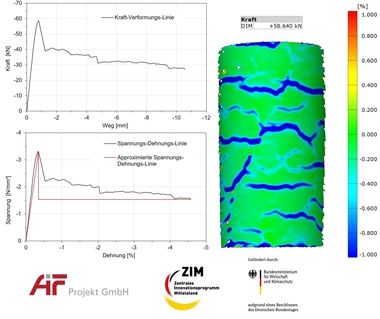

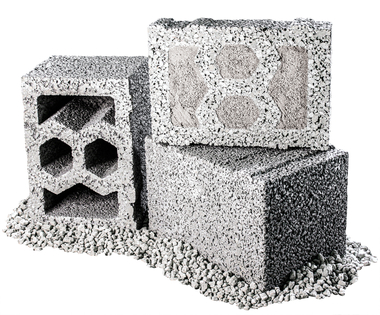

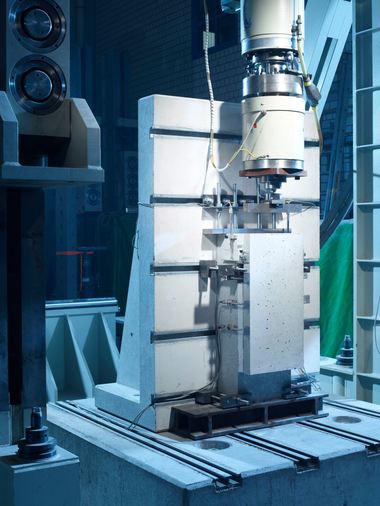

In a research project (SWD-10.08.18.7-15.20) commissioned by the Bundesinstitut für Bau-, Stadt- und Raumforschung (Federal Institute for Research on Building, Urban Affairs and Spatial Development), monolithic, load-bearing and simultaneously heat-insulating, EnEV-compliant (Energieeinsparverordnung; Energy Saving Ordinance) wall elements consisting of exterior ultra-high-performance concrete (UHPC) shells with a chemically foamed, purely mineral interior foam concrete have been developed for use as precast concrete elements. The foam concrete is based on a fine-particle UHPC mix and, unlike aerated concrete, is air-hardening and does not require autoclaving. This structurally optimized, low-density foam concrete offers high thermal insulation properties and high strength at the same time. The wall element is purely mineral and, in contrast to standard wall elements, can be fully fed back into the building materials cycle. Design results of the hybrid wall elements show them to be ideally suited for use in building construction due to their mechanical properties and fracture behavior, since the composite bodies can absorb loads to an adequate degree and display visually perceptible debonding of the UHPC shells from the foam concrete core only in the post-fracture stage. The results show that, for the ultimate limit state, the design can be based on the ultimate load. In the serviceability limit state, however, the design should be based on a load lower than the first ultimate load. Load transfer and construction-related physical properties are ensured in the wall element.

On the campus of the University of Kassel, a temperature-controlled demonstrator has been built from the hybrid wall elements with the aim to examine the construction-related physical properties of the wall elements on a long-term basis. In the process, sensors are used to record the differences in temperature at different points in the demonstrator. The aim of these investigations is to obtain information on the heat transport within the wall elements and objects made from them.