Master computer celebrated world premiere

At this year’s Bauma, Unitechnik presented its Unicam.10 master computer, the completely re-developed version is to allow the users in the precast concrete industry to increase their productivity.

UniCam.10 coordinates all working steps of the CAD/CAM-controlled production process of precast concrete components. This includes the order management, the assignment of pallets, the production control, the logistics and the information management. For the automated pallet assignment, the UniCam.10 makes use of a new optimization algorithm, which leads above all to significant improvements when it comes to nesting of elements. The uniformly timed sequence of the pallets enables the users to increase their productivity during the manufacturing process. For the data exchange between UniCam.10 and CAD as well as the connected production machines, the master computer supports all versions of the CAD-CAM interfaces of Unitechnik, including the latest XML version. If a factory uses different versions, UniCam.10 converts the data accordingly, thus avoiding any loss of information. In order to further improve the quality and the operating efficiency, the Unitechnik optionally offers a CAD viewer as an addition to the master computer. The application can be installed on any PC and checks job order data of precast concrete elements for plausibility before production release.

Ergonomic software design

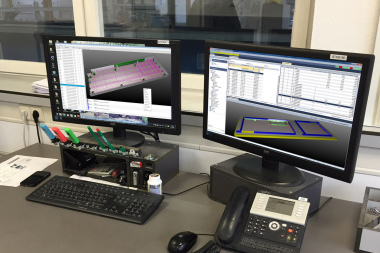

Unitechnik also attached importance to an ergonomic user interface when developing the new master computer. The users can configure their screens according to the individual requirements and can freely scale the display resolution. Furthermore, they can access the master computer by means of mobile devices such as tablets or smart phones. The plant visualization can be zoomed infinitely, similar to Google Maps. A sidebar, which is permanently visible, shows the most important information regarding the production status.

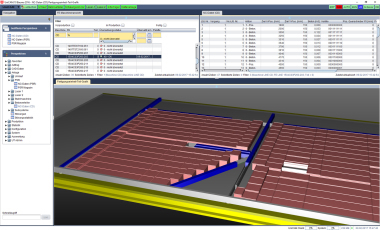

As another new feature, the master computer allows the simulation of the entire precast concrete plant on the PC in a three-dimensional representation. Users benefit from this feature, for example, when planning a new factory, optimizing existing plants and training the operating staff in the virtual precast concrete plant.

Future-oriented development environment

Unitechnik utilized synergies with other business segments for the development of UniCam.10. The company, for example, seized many basic modules of the UniWare storage management system. Now, the master computer for the precast concrete industry is based on the programming language Java like UniWare. In this way, it is possible to implement further developments of one software analog into another one respectively. Hence, Unitechnik creates a future-oriented software platform, guaranteeing their customers long-term security of investment.