Manhole weighing 95 t for the Port of Hamburg

Quite recently, the quality products made by Berding Beton have been in demand for a project at the Port of Hamburg. At special parts of the harbor there are so-called turning points for vessels. These turning points are often quite narrow for the vessel lengths usual today. In order to produce relief, it was decided to dismantle the Tollerort container terminal on the north side so as to enlarge the turning point situated there by about 70 meters.

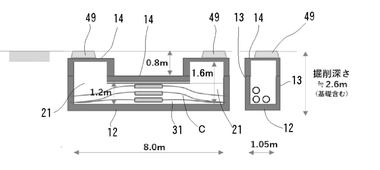

As part of this building proj-ect, the redesign of the drainage became necessary simultaneously. It was additionally planned to cutoff the storm water sewer system before draining into the river Elbe, so as to prevent any materials hazardous to water from flowing into the river Elbe in the event of accidents on the site. This should be implemented by a building structure comprising nominal pipe sizes of DN 1200 and an additional branch of DN 500. Berding Beton has been won as partner for supplying the material. For one thing, pipes made of reinforced concrete were needed, which are particularly suited to all hydraulic and static challenges and withstand extreme loads. For another thing, the building contractor, Eggers Tiefbau GmbH in Tangstedt, decided to realize the huge outlet structure in a construction method based on precast concrete elements.

Manhole base weighing 54 t

Berding Beton was not only able to meet the high quality requirements by their customized production of the sections requested, thanks to the possibility of fast installation, they also contributed to an efficient solution. It just took three days to install the manhole with an overall weight of approx. 95 t, including the earthworks. Four individual parts had to be assembled properly: a base and upper section as well as a two-piece cover plate. The base section alone was weighing about 54 t, requiring a 500-ton crane to install the same.

Thanks to the good collaboration of all parties involved all works were carried out without any problems, so that a perfect concrete structure was finally inaugurated.