Increasing energy efficiency in precast concrete products production

It is a known fact that curing is a significant part of the production technology for concrete and reinforced-concrete products and is connected with high energy consumption. Structure analyses for heat consumption in the construction industry indicate that a large portion of this is attributed to the steam generated in curing precast concrete products and for heating inert materials, such as gravel, sand, expanded clay, and process water.

Due to the design characteristics, conventional boilers are not always able to effectively regulate the steam flow, depending on the requirements of production, which can cause overloading. Many precasters are forced to run their boilers inefficiently at minimum load, even when no steam is required. This leaves part of the energy unused, unnecessarily eating up a great deal of money. The nearly 20-year-experience of the Moscow-based engineering company Interblok in research and product introduction shows that the actual requirement of thermal energy in production of precast concrete products, according to manufacturers, can be reduced to a fraction by using a modern series ST steam generator.

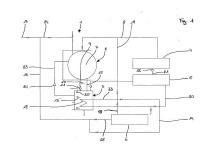

Efficient steam generator

One of the solutions for basic energy efficiency of companies in the construction industry is to set up autonomous decentralized heat plants based on the use of high-efficiency steam generation of the Interblok Series ST. The technology used for generating process steam is already successfully used in several countries, e.g., in Great Britain, Kazakhstan, Canada, Norway, Russia, the USA, the Ukraine, Belorussia, and South Korea.

Steam power operation was already modernized in more than 50 companies and energy-efficient use for curing precast concrete products in day-to-day operation demonstrated: consumption of process-related natural gas for production of precast concrete elements could be reduced by an average of two-thirds of the original use.

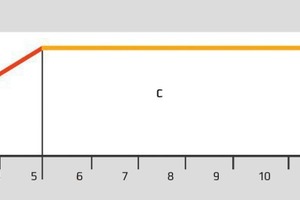

Evaluation of the temperature diagram (Fig. 2)

Zone A: Hardening process of the precast components within 2 to 3 hours by increasing the temperature through the heat-emitting process of cement hydration up to 30 to 35 °C.

Zone B: Temperature up to 80 °C based on predetermined speed by addition of process steam from the steam generator, operating from 2 to 3 hours to full capacity.

Zone C: Maintenance of isothermal operation of 60 to 80 80 °C; the steam generator operating at lowest capacity from 5 to 6 hours.

Zone D: Cooling of the precast concrete components within 4 to 5 hours, the steam generator switched off.

Text: Dr. Oleg Bogomolov