G&J Industries installs Extruder X-Liner to boost

production capacity for 60 cm wide hollow-core slabs

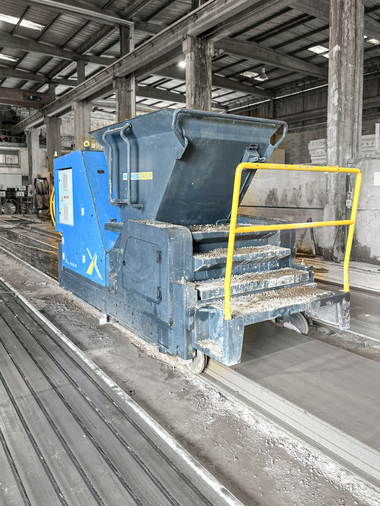

G&J Industries, a future-driven Belgian family business producing prestressed concrete elements, decided to boost its production capacity by adding an Extruder X-Liner from Echo Precast Engineering.

Family-owned business supplies products across Belgium

G&J was founded in 1999 by its owner Gerard Oben, who is now working with his two sons, Jan and Johnny. The company specializes in hollow-core slabs, solid floors, T-beams, stakes, and full and core lintels. With hollow-core slabs being 50% of their production output, the family-owned company supplies products across Belgium. In 2020, the company purchased a new Extruder X-Liner from Echo Precast Engineering, a Progress Group company based in Belgium, to stay ahead of the competition and increase production capacity. This new machine operated on 1.2 m wide production beds makes it possible to produce two slabs at the same time for an increased output of the highly demanded 60 cm wide slabs.

Efficient automated production of hollow-core slabs

The innovative company was the first in Belgium to have their prefabricated elements certified to the CE mark and the BENOR mark, demonstrating that their constant drive for quality and process improvement is successful. 90% of the products are manufactured on demand, while only 10% are held in stock. In a nutshell, the process of producing hollow-core slabs is simple: Screws spread the concrete on the production bed, followed by compaction and curing on the production line. Automation of this process requires tried-and-tested equipment.

G&J normally uses slipformers but has now chosen to expand their range of machines by the Extruder X-Liner® from Echo Precast Engineering to increase the production output of 60 cm wide slabs. This high-performance machine has been specifically designed to meet the needs of precast producers in the residential and commercial sector, who require 0.6 m wide elements in addition to the standard 1.2 m, 1.5 m and 2.4 m options.

The Extruder X-Liner

The Extruder X-Liner FC (Flow Compaction) has been designed to produce hollow-core slabs in an automated process and is easy to manage for the operator. The Extruder X-Liner installed at G&J Industries works on 1.2 m wide beds and produces two 60 cm wide, 160 mm or 180 mm high hollow-core slabs. This versatile machine is also capable of producing hollow-core slabs in widths of up to 1.2 m simply by exchanging a few components.

The modular X-Liner® is suitable for producing two 60 cm wide, 160 or 180 mm high slabs (with four cores) simultaneously. Its unique combination of screws and a center mold piece to split the slabs ensure excellent compaction and quality of the 60 cm wide slabs, which are very popular for residential construction in Belgium, but they are also perfectly suitable for use in industrial facilities, schools, etc.

G&J ordered an X-Liner with a versatile nozzle unit to also produce nine-core slabs measuring 160 × 1,200 mm and 180 × 1,200 mm.

Company owner Gerard Oben comments on the new addition: “The quality of the hollow-core slabs is really good – it is the same quality as provided by a slipformer with an additional nice finish on top“, and adds: “The machine is very good and quick. We like that it does not make noise, and nobody is needed to drive the machine. The machine can self-drive, so we need only one person to get the concrete to the casting machine.”

Shark screws ensure excellent performance

The maintenance-friendly X-Liner provides a high degree of flexibility; it can be individually adjusted to produce different slab heights in a short amount of time. Also, the ratio between load and span can be adjusted by changing the concrete strength parameters and the reinforcement layout to suit specific applications. As a result, production time, wear and tear are reduced, and the entire process is easier to plan and handle, in addition to the time saved. Its “shark screws”, specifically designed for this machine, make it possible to minimize the back rotation of the material inside the machine so that less power is needed for compaction, which increases the production rate significantly, combined with better compaction and a long service life.

The X-Liner is equipped with the integrated stabos software system from Progress Software Development, another Progress Group company, which stores the production data locally and subsequently integrates it into the web client. Additionally, the machine includes a wireless connection for remote control from anywhere.

CONTACT

G&J Industries

Heesterveldweg 9

3700 Tongeren/Belgium

+32 12 391 380

Progress Group

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979-100