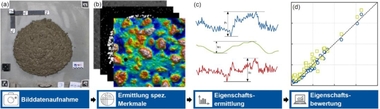

Estimation of fresh concrete behavior on the basis

of the concrete composition

Normally, the fresh concrete properties are specified in the planning stage of building structures – generally, these are just the exposure classes and strength classes. Then the consistency class and maximum particle size are added by the building contractor. In most cases, neither purchaser nor supplier think about the question of how workable or how sensitive or robust the concrete will be in terms of segregation and dehydration. However, most of the problems in hardened concrete result from the properties during pouring, such as an addition of water because it cannot be poured, or settling of the coarse aggregate with an accumulation of mortar at the top, or drying out of the surface because there is not enough protection water from bleeding (the specification often requires must not bleed) or an early treatment (before being hardwearing) does not take place, for example. But it is relatively easy to estimate the fresh concrete behavior from the concrete composition, as the presentation will be shown.

Decisive aspects are in particular:

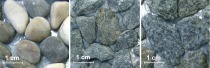

Aggregate particle size distribution curve, how much void does exist, how much surface has to be wetted and how is the supporting effect of the particles which prevent or impede subsiding.

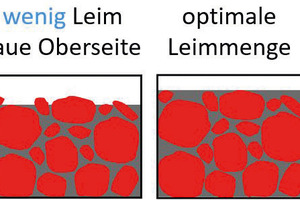

Volume of cement paste, whether this is sufficient for filling the voids and for the lubrication between all aggregate particles, if not, even plasticizers or superplasticizer cannot achieve a workability. If there is too much cement paste, the aggregate particles settle and a watery fine mortar remains on the surface which hardens later and will get shrinkage cracks (Fig. 1).

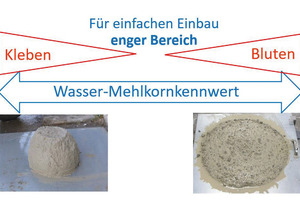

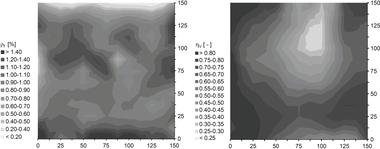

Stickiness of the cement paste, which means an estimation of the cohesiveness based on water content and powder content (Fig. 2). Thus, segregation during pouring (bleeding and settling of the coarse aggregates) is facilitated by a “too low viscosity”, whereas if being “too sticky” often leads to difficult pouring conditions or even to the fact that pouring is not possible at all (normally resulting in a “forbidden” addition of water).

In principle, concretes with a low compressive strength and thus a higher w/c ratio and a lower cement content/powder content are always “soft” and often already “too soft”. Hence, they are already segregated during pouring through (forbidden) volume expansion and intensive vibration. On the contrary, concretes ≥ C35/45 and w/c < 0.45 are always “sticky” and partly on the threshold to “too sticky”, therefore, the pouring openings, filling quantities and vibrating devices must be adapted accordingly and the concreting crew must be trained correspondingly. If this does not happen, in building practice, the stickiness is reduced by the addition of water. Simple correlations and formulas for estimations will be presented and explained in the presentation. In future, it will be reasonable to clarify in advance either which pouring method is required for the estimated pouring behavior or which concrete shall be ordered for the specified pouring method.