Dimensioning and realization

Bridge construction is a reasonable field of application for carbon-reinforced concrete. The corrosion-resistant reinforcement requires a small concrete cover. Moreover, a protective layer can be eliminated completely. This enables the construction of sustainable bridge structures which may be more efficient as conventional construction methods not only with regard to the service life but also during production. Already implemented bridges demonstrate these advantages and encourage more and more structural engineers to design with this new material.

The dimensioning of carbon concrete bridges slightly differs from the common methods which are known from reinforced concrete construction. The material law for concrete can be adopted from EC2. A linear-elasticity approach can be chosen for the carbon-fiber reinforcement. Therefore, the reinforcement required for the bending design can either be determined by a closed or iterative approach. At present, the shear design is only required for structural members without shear reinforcement and is based on the approach of EC2. Both verifications do not require any investigations of the load-bearing capacity. However, experimental tests are still needed for bridge girders which require shear reinforcement. The existing safety concept provides a partial safety coefficient of γnm = 1.3 for the reinforcement.

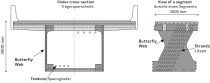

Five carbon concrete bridges were implemented in the last year. This is almost the same number of structures as altogether in the last ten years. It obviously indicates the large interest and the feasibility. Three of the bridges are situated in the area of the garden show in the Remstal valley and are a combination of carbon-reinforced concrete and wood. This version is an environmentally-friendly solution due to the low CO2 emission in the manufacturing process. Another example is the first road bridge completely made of carbon-reinforced concrete in Gaggenau and the hybrid bridge in Ottenhöfen (Fig.) made of steel girders and a slab made of carbon-reinforced concrete.