Digital concrete enhancement as innovative system solution

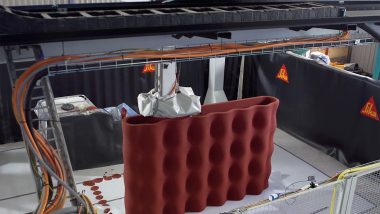

CTG-PrintTec GmbH presented its brand-new series system “Jaguar 1,200” for digital decor printing of concrete slabs in July 2015 at SR-Schindler’s in-house exhibition. The holistic solution approach, according to the manufacturer, resulted in a system that enables manufacturers of concrete products to turn the conventional standard concrete slab into a lifestyle luxury product with nearly unlimited decor possibilities. The digital technology makes it possible to change decors at the push of a button, providing high flexibility for creativity and individualism.

The technology, moreover, does not require expensive additions, leading to cost savings that should not be underestimated.

This system solution for concrete patio slabs comprises the complete automated printing technology with special concrete colors and has a printing range of 1,200 x 1,200 mm. One of these plants, with daily production capacities of up to 1000 m², was already delivered to the company Excluton in the Netherlands.

System suitable for patio slabs and façades

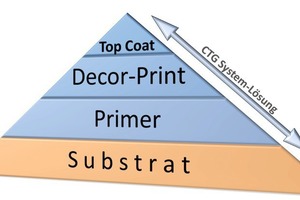

The digital decor concrete printing proc-ess is also suitable for use on façades and offers architects and builder-owners the benefits of individual design, making it possible to merge the façade with the overall appearance of a building in a new way. Concrete is a complex substrate. For a system solution like digital concrete enhancement to function, a chemical system solution is required in addition to a mechanical solution. Another special component is the weather-resistant CTG Concrete Ink, which has a very high UV resistance and a superior resis-tance to chemicals, as well as being specifically adjusted to the printing system.

The name CTG-Print Tec GmbH stands for “Industrial Functional Design Printing,” explains CTG Sales Manager Chrysanth Duda. “On the basis of the knowhow sectors printing technology, automation and chemistry, individual solutions for industrial inline printing process are implemented and merged with the key core competencies of chemistry and mechatronics. The sum total of this we put in our brand name Chematronix, of which the system solution for digital concrete enhancement is a prime example.”