A precast garage with glass fiber reinforcement and with national technical approval

The use of textile concrete enables easier and more environmentally friendly manufacture of precast garages. In a cooperation of Solidian, Beton Kemmler and RWTH Aachen University of Technology, a garage concept with glass fiber reinforcement was implemented for the first time by Solidian. This represents a worldwide innovation that just now has been granted technical approval by the German regulatory authorities for construction.

A garage is generally utilitarian space, which, apart from its use as parking space, often serves as a flexible storage facility: e.g., for power tools and garden accessories. For this reason, dryness, cleanliness and durability are key requirements placed by the end customers. Precast garages made of concrete meet these requirements and have in recent decades proven themselves in practice. However, to ensure long service life when using reinforced concrete, measures to guard against the danger of corrosion are necessary. This requires high concrete cover, which means high product weight. The consequence: production and transport become relatively complex and have unfavorable effects on the CO2 balance of precast garages manufactured according to these requirements.

No corrosion, no repair

Glass fiber reinforcements here represent one solution, since textile concrete does not corrode and enables significantly thinner construction elements. This makes for more useful space available per area unit, and there are no repair costs for corrosion damage that would otherwise inevitably occur over the long term.

Textile concrete, moreover, has great dimensional stability, and its tensile strength is six times that of conventionally reinforced concrete.

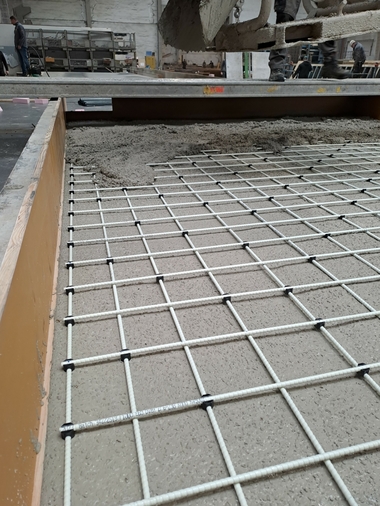

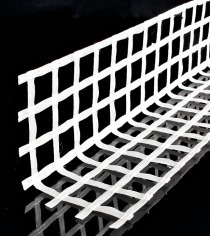

For the world’s first precast garage with national approval, a development partnership – between the precaster Beton Kemmler and Solidian, a specialist for glass fiber reinforcement – has proven to be especially successful. For construction of the garage body, an innovative material combination was used of glass fiber fabric impregnated with epoxy resin, Solidian GRID Q121/121-AAE-38, and glass fiber bars, Solidian REBAR. In this way, flexible individual garage modules can be manufactured that can be readily combined to double or large-area garages and used for various target groups and purposes. The elements are cast from one mold, thus enabling monolithic connection of walls and floors. The thinner wall thickness results not only in greater space of 4 cm width in the interior but in significantly lower weight as well, so that the body of an individual garage (6 x 3 m²), without bottom slab, weighs only 6.4 t – compared to the 11.5 t of a conventionally reinforced concrete body.

Ecologically sustainable

The manufacturing process can be implemented highly efficiently, because the individual reinforcement fabric mats are already formed and cut to size during textile manufacture. This enables placement of the complete reinforcement cage into the form after only a short time, with subsequent casting. The hardened garage needs only to be removed from the form and connected to the bottom slab. The slender construction design provides freedom for positioning the door and window openings.

The use of glass fiber reinforcement benefits both the manufacturer and the construction planner and, not least of course, the environment. Analyses conducted by RWTH Aachen University of Technology clearly verify that large-size structures with complex loadbearing behavior on a high safety level can also be implemented with textile concrete. The consequences of the technological change tending towards glass fiber reinforcement primarily impact the environment and contribute to ecologically sustainable building.

The successful start-up proj-ect clearly demonstrates concept readiness for series production and opens the market for Solidian reinforcement to include additional interesting product solutions.