Three-stage concept for the development, production and quality control of SCC

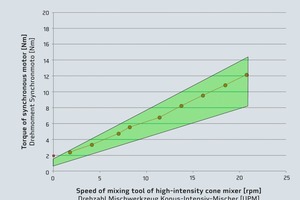

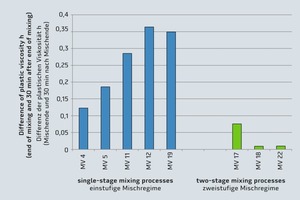

The mix design of a durable, self-compacting concrete that is optimized using the software BétonLab Pro results in longer mixing times, which can be reduced significantly by applying multi-stage mixing processes in a high-performance cone mixer. In addition, the rheological characteristics of the concrete can be determined in the mixer for quality control purposes.

When developing new concrete mix designs, the durability of the concrete and the amount of primary energy consumed in the production process are becoming increasingly important over and above the traditional design requirements. In this setting, the outcome of the life cycle assessment is determined by the Portland cement clinker and plasticizer content in the mix. This inevitably leads to the requirement of reducing the amount of Portland cement whilst adding only a minor amount of plasticizer. In addition, a reduction in the water-binder ratio (which further reduces the paste content) is...

![3Torque-controlled measurement of the yield value [Nm] in the high-intensity cone mixer](https://www.bft-international.com/imgs/4/6/2/4/9/0/tok_05380a8f4b3105b16c0e507333afdc68/w300_h200_x400_y267__800_535.-b7784a4621b4643a.jpg)