Optimized production of prefabricated parts with a Concrete Distributor from Weckenmann

For Melbourne Precast Concrete (MPC) in Melbourne, Australia, the past year 2010 was an important milestone in the young company’s history since its acquisition by Derek Finocchiaro and his partner Shane Evans five years ago.

The stationary production with a capacity of around 1,000 sqm / day, mainly for the production of solid walls, has been further optimized for instance by means of a concrete distributor from the company Weckenmann.

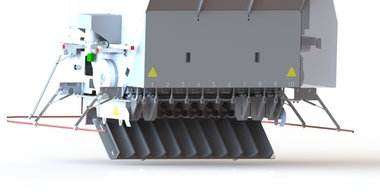

After replacing the usual ready-mix concrete truck mixers, with which the concrete was cast on the tables, by a new batching plant and bucket conveyor for the concrete supply, the subject of how to cast precisely and fast, was solved by an imposing and record-breaking concrete distributor from Weckenmann with a bridge span width of over 28m.

According to the common definition of the requirements for the new machine by owner Derek Finocchiaro Melbourne Precast and Dietmar Kiene, sales engineer at Weckenmann, the concrete distributor was designed exactly according to the requirements of the customer Melbourne Precast by the design engineers at Weckenmann. „In order to optimize the transport costs for the long journey, the machine was dismantled, this enabled cost savings of more than 50% for the transport“ says Dietmar Kiene.

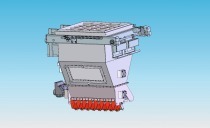

Utilizing an internal lifting and turning gear, the discharge container can be brought into the right working position according to the various precast concrete products. The slide technology and the slide width adjustment device have proved its excellence hundreds of times ensuring a perfect concrete discharge for almost all concrete consistencies.

By means of the slide width adjustment device, the slide outlet diameter can be immediately and individually adapted to any concrete consistency by the touch of a button. This applies for self-compacting concrete too. Equally, a uniform „concrete curtain“ is discharged with the slide technology in combination with the spiked roller /distribution roller.

Another advantage of the slide technology is the unbeatable low maintenance and cleaning costs compared to other discharge technology such as dosing screws or discharge conveyors. The wear of the slide technology is relatively low. By experience customers discharge about 20.000 cbm of concrete before the discharge unit must be reconditioned. A comparable screw spreader unit has an annual renovation cost for the renovation of the discharge unit of around 10.000 €. Renovation costs for sliders is only 1/3 of the screw technology cost.

The discharge container with slide technology is very easy and fast to clean and an integrated door on the side of the container makes the cleaning process significantly easier. The weight of the concrete inside the bucket is displayed on a digital weight display.

Two built-in screeds on the concrete distributor allow an immediate levelling and closing of the concrete surface. By means of a manual helicopter trowelling machine all precast concrete parts can be subsequently smoothed to the highest surface quality.

For MPC this investment was a valuable step towards the optimization of processes and further improvement of the product quality and thus the positioning the young company in the market. The strong economy and job situation for 2011 allows the company owner Derek Finocchiaro to look ahead positively. With justifiable pride he points at his new machines and he knows that he is adequately equipped for the future. In Greater Melbourne there are almost 50 precast concrete plants and therefore you need a c onsistent high quality level of performance that MPC can guarantee through his investment. Australia has around 22 million inhabitants, of which about 4 million people live in Greater Melbourne. Therefore Melbourne is for precaster a very interesting market.

Company Melbourne Precast Concrete produces mainly solid walls for industrial and residential buildings, but their product range include also stairs and beams and other precast concrete products, that rounds out their product portfolio. MPC has about 75 employees, of which around 40 people work in the production.