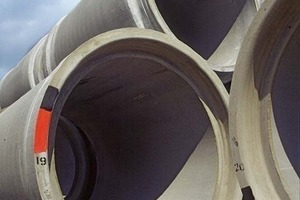

Competitive advantages of concrete pipeline systems

Sustainable construction has become a top priority issue for the UK drainage and sewerage construction sector. This is due to a new obligation imposed by the UK water industry regulator OFWAT on all water/wastewater companies to evaluate the environmental and social impacts of their businesses. Since then, an increasing demand has emerged in both the water and wastewater sectors to understand how sustainability can be implemented throughout the industry. Concrete pipeline manufacturers realized the scale of these requirements at a very early stage and have been successful in identifying a number of means to tackle different sustainability challenges. Concrete pipeline solutions can now offer a competitive and sustainable option to the water supply and drainage/sewerage sectors. This article is based on an upcoming publication by the Concrete Pipeline Systems Association (CPSA), and illustrates the “sustainability case” for concrete pipeline systems.

There is a number of sustainability-related competitive advantages that concrete pipeline systems manufacturers can benefit from. These cover a wide range of sustainability measures as demonstrated below.

Emissions and embodied energy

Most of the impacts linked to concrete are generally associated with upstream activities. A few years ago, the TESCOP1) LCA study estimated that cement use contributed to over 70% of the total cradle-to-gate nitrogen oxide emissions and around 50% of the embodied energy of a concrete sewer pipe [1]. The concrete pipeline systems sector has benefited considerably...