ConcreTec – new assistance system for concrete compaction

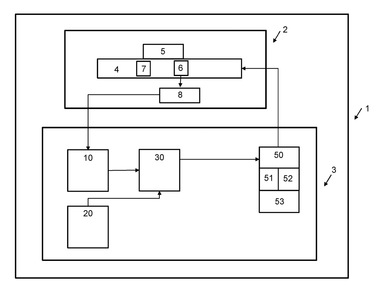

With ConcreTec, precast elements can be compacted in clearly and simply organized procedures, and in reproducible quality. ConcreTec is a data-based assistance system for the compaction of concrete. Plant operators receive objective information on the compaction process and on the compaction progress in real time.

The compaction model on which the system is based not only considers the geometry of the concrete element but also the properties of the fresh concrete. Furthermore, information flows into the model during the compaction process. This includes current process variables such as vibration strength and frequency during the compaction process. ConcreTec helps to prevent incomplete concrete compaction and noise pollution due to unnecessary compaction.

Simple handling

ConcreTec, according to the manufacturer, is easy to operate on a well-organized touch display. The descriptive representation of the momentary production situation and of the relevant process variables enables the operator to make correct preselection of external vibrators and to track the compaction process.

ConcreTec provides the production staff with a clearly organized workplace that helps to prevent basic error sources.

ConcreTec offers the operator fundamental data-based information to objectively assess the compaction process. That means, in specific terms:

Display of the vibration level: if the vibration values are outside the favorable range, external vibrators can be switched on or off.

Display of the compaction progress: the compaction process can be terminated when the desired target value is attained.

Increased process reliability

ConcreTec helps to improve production flows and to prevent quality risks. Because, with ConcreTec, the desired compaction result of the precast element no longer depends on the experience of individual staff, but assists the decision-making process on an objective data basis.

For the data of the compaction process are stored for quality assurance and documentation and made available in a well-organized protocol. In this way, manufacturers are able to document the compaction process clearly and simply and to use it to document compaction procedures.

CONTACT

Wacker Neuson SE

Preußenstraße 41

80809 Munich/Germany

+49 89 35402-0