A Stellar modernization of construction in the National Capital Region of India – with precast concrete elements

Well-known Indian Stellar Group, which has been successfully doing business in the construction industry for over 25 years, is convinced that precast is the future of the building industry in India. To stay ahead, they have expanded their portfolio with a hollow-core production line from Ultraspan, a Progress Group company, in close cooperation with the Indian subsidiary of the group, Progress Precast India. Even under the special circumstances during the Covid-19 outbreak, the companies managed to deliver and install as well as instruct Stellar on the new machinery, which is now benefitting the industry leader in many ways.

Focus on commercial and residential buildings

Focusing on commercial and residential projects, Stellar has developed over 9 million sq. ft. in the residential and commercial sectors. Current major projects, such as a residential development on an area of over 16 acres and three commercial projects close to 1.5 million sq. ft., are benefitting from the use of precast concrete elements. The main scope of delivery encompasses the National Capital Region (NCR) of India, which includes the cities of Greater Noida, New Delhi, Gurgaon, Faridabad, and Ghaziabad.

Why is precast the future of building?

“Building in general is becoming troublesome as the shortage of skilled manpower is huge and we feel this problem will increase in the future. So we are of the opinion that precast and the factory-based production of it is the only way to reduce the requirement of manpower, with the additional benefits of higher quality, saved time and better worker safety. We believe precast is the best option going forward,” states Mr. Akshay Sethi, Director of Stellar Group, on the current situation and how it influenced the decision to build with precast and to invest in a precast plant.

According to Stellar, in the beginning they had some similar commercial projects, which lined up in the last few years. This is why shifting the focus to constructing with standardized precast also with regard to those projects just made more sense. This applies particularly to commercial buildings since wider spans and greater clearances can be implemented with precast. Besides, precast provides the benefit of shortening the construction time by up to 50% thanks to the fact that the elements can be produced at the plant independently of weather conditions, and the machines can work around the clock, according to the expert from Stellar. In addition, product quality is consistently high since element manufacture takes place on a highly automated production line. The elements consistently conform to a quality standard that would not be achievable with conventional construction methods, which include too many factors that can compromise quality and, consequently, often the speed of construction if defects need to be remedied. In addition, safety remains a big concern and is much easier to ensure when producing and building with precast elements.

Automated machinery for precast

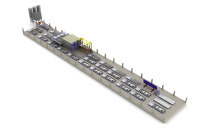

In 2021, the latest precast machinery was installed at the Stellar plant. With the Ultraspan extruder and a state-of-the-art concrete sawing machine, the hollow-core slabs for the projects can be produced quickly and to a consistently high quality standard. Presently, two different slab thicknesses are being produced at the plant: 250 mm and 320 mm, with the option to adjust the size between 100 mm and 400 mm using an easy-to-exchange cassette. These hollow-core slab dimensions cover a wide range of construction endeavors satisfying a broad variety of structural requirements in today’s demanding projects. The current production capacity is based on four 145 m long casting beds. These newly installed casting beds and the recently delivered, hydraulically powered tilting tables from Progress Precast India increase the plant’s daily output, and products can be delivered to new projects on time and to an impeccable quality standard.

“What we have seen is that the hollow-core machinery from Ultraspan/Progress Precast India turned out to be more efficient compared to other hollow-core equipment. We realized that the void ratio was much greater, and safety has improved, too. The machine is relatively simple to understand and handle and can be maintained very easily. Even if a problem comes up, it can be resolved very quickly, so downtime is reduced and we are very satisfied with it,” states the project manager, Mr. Gaurav, confidently.

There were some hiccups due to Covid-19 and Progress had to commission this hollow-core equipment remotely because of the related restrictions. Nevertheless, Stellar was able to start up production and move on with their projects quickly thanks to the service provided by Progress and although remotely advised. The equipment manufacturer’s local office was also able to enlist the service of a local engineering partner whose team provided on-site support to Stellar while, obviously, complying with the Covid-19 restrictions. So even during these difficult times, the Indian subsidiary of the worldwide renowned Progress Group was able to come up with an appropriate solution.

What are the plans for the future?

“What we are targeting right now are commercial projects and industrial construction. We are also getting enquiries from vendors who need precast solutions for their projects,” says the project manager. The warehouse market has gone up for various reasons, so the market is increasingly shifting towards building with precast, being aware of its compelling benefits especially for commercial buildings. In addition, steel prices have increased significantly, which is why the trend is moving from conventional to precast buildings in the commercial sector already. “Apart from that, we are planning to expand our precast factories also for residential development,” concludes Mr. Gaurav, looking forward to an exciting future with precast taking the lead in all segments of the Indian construction industry.

CONTACT

Stellar Corporate Office

C 56/9, Stellar Head Office, Noida Sector-62

201309 Uttar Pradesh/India

+91 120 455 0250

Progress Precast India Pvt. Ltd.

C-585 Basement Defence Colony

110024 New Delhi/India

info@progress.group

Ultraspan

165 Fennell Street

Winnipeg, MB R3T 0M6/Canada

+1-204-992-3200