The sustainable concrete of tomorrow

Present sustainability of construction materials

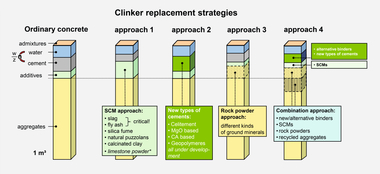

The sustainability debate has played an important role for many years also in the construction industry and in particular in concrete construction. Efforts to improve the sustainability of concrete are accompanied by fundamental changes in concrete technology: Portland cement clinker has, to a large extent, been replaced by secondary cementitious raw materials such as granulated blast-furnace slag, fly ash or limestone powder, which results in problems with controlling the properties of fresh concrete and in an altered development of strength. An additional trend goes towards combining several types of binders (3 or more) into one binder or replacing Portland cement clinker by new types of binders such as calcined clays or Celitement [1]. Finally, various authors – including those of the present contribution – presented concretes with a significantly reduced cement or cement clinker content [2, 3, 4]. The latter will in the following be referred to as green concretes.

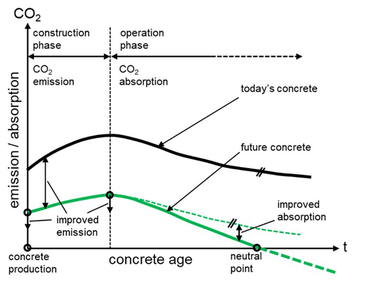

In a first step, the approaches and exercises mentioned above aim at minimizing the environmental effects associated with cement and concrete production. Depending on the approach chosen and the parameter examined, the environmental effects of concrete production can be reduced significantly in comparison with standard concretes not optimized from an ecological point of view. The question must currently be asked, however, as to whether such a reduction in environmental effects will ultimately not be made at the expense of the sustainability of the construction material or structure, since not only low environmental effects but also high performance and durability are required in particular for the construction of civil engineering structures (equation 1).

The above exercises will result in sustainable structures only if the potential for sustainability of the construction material is utilized by the designer and is not compromised by mistakes in design or construction. Standardized procedures can be used to identify the environmental effects shown in equation 1 by means of a life-cycle assessment according to DIN EN ISO 14040 or DIN EN ISO 14044, respectively. As a rule, the performance of the concrete can be expressed, in simplified form, via its characteristic compressive strength. Calculating the potential service life of the structure and thus of the concrete, however, poses a challenge. To do so, the service life of the concrete must be calculated as a function of one or several environmental effects occurring in combination. The approach used to calculate the potential for sustainability of concrete is explained below, using a green concrete with a low cement content as an example.

Sustainability benefits of green concretes

Table 1 shows the composition and additional selected properties of different green concretes developed at the Karlsruhe Institute of Technology (Karlsruher Institut für Technologie), as well as those of a reference concrete according to [5]. As the global availability of, for example, fly ash, granulated blast-furnace slag or other pozzolanic materials is limited, the use of these substances was completely eliminated from concrete development. Pure Portland cements were used instead, their application rates being reduced in increments. To ensure adequate performance and workability, the granulometric composition of all granular source materials was optimized for each mixture by means of packing models. The course of action pursued in concrete development and the source materials used are described in greater detail in [4].

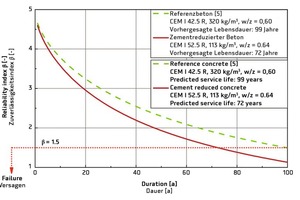

The test results show that concretes with very high compressive strength values of up to approx. 70 N/mm² and correspondingly high performance can be produced even with cement contents as low as approx. 110 kg/m³. Workability of the concretes currently remains a critical factor despite the use of state-of-the-art concrete plasticizers. Concrete durability was evaluated by testing the carbonation resistance and chloride migration resistance as well as freeze-thaw resistance [6]. These show that the green concretes developed are of reduced durability. To verify the resulting consequences for the potential service life of a structure, a service-life design was performed for an incident of carbonation-induced reinforcement corrosion. Full details of the exact procedure can be found in [6]. The carbonation resistance of the concrete determined in experiments (Table 1) and the concrete cover of the reinforcing steel c, which in this case was selected at 40 mm (standard deviation 8 mm), were used as input values for the design. The service life of the structure, or the limit state considered to be decisive for the same, has been reached when the carbonation front reaches the reinforcement with a given probability (expressed by the so-called reliability index β) (Fig. 1). Using the service life thus calculated, the potential for sustainability of the concrete can then be quantified by means of equation 1.

Construction material-sustainability potential ~ Service life ∙ Performance⇥(1)

Environmental Impact

The results show that, due to its significantly reduced environmental effects and increased strength-specific performance, and despite slightly reduced durability, the concrete with a cement content of 113 kg/m³ exhibits a significantly higher potential for sustainability than the reference concrete with a cement content of 320 kg/m³. Even though this calculation is doubtlessly based on various simplifying assumptions, the result unquestionably shows the way forward in increasing concrete sustainability. The green concretes presented will, however, be more sustainable in comparison with conventional formulations only if their performance and potential service life are exploited by the designer on the basis of adapted rules and regulations.

Future challenges

In the years to come, the challenge in developing concretes offering the highest potential for sustainability will, on the one hand, lie in improving the fresh concrete properties and workability of cement-reduced concretes. This is of particular importance as poor workability properties are frequently accompanied by incorrect workmanship reducing the service life. On the other hand, the methods for calculating the potential service life of the structure need to be improved further and extended in particular by the complex influence of combined environmental effects. In addition, a vital but certainly not easy step will be to update the rules and regulations of concrete construction taking into consideration the properties of these new types of concrete.