Strong partner for Bamtec reinforcement technology

Bamtec reinforcement technology stands for a highly efficient process for planning, manufacturing and installing surface reinforcement for reinforced-concrete ground slabs and walls from the company BAM AG in St. Gallen, Switzerland. Bamtec elements are effectively used instead of conventional reinforcement. They consist exclusively of uniaxially installed round bars, connected to an assembly unit by horizontal support bands. The cost-effectiveness of this concept results from the systematic use of electronic data in reinforcement planning and manufacture, maximum material efficiency and resource optimization in every step of work. The principal advantages over conventional reinforcement are savings in reinforcing steel, reduction of installation time of between 80 to 90 % and, at the same time, improved quality.

The company Progress Maschinen & Automation AG, part of the Progress Group, a highly efficient, innovative manufacturer and developer of machines and systems in the reinforcing steel processing sector, is a strong partner for fully-automated production systems for the manufacture of Bamtec reinforcing elements. The company supplies bending systems, precasting plants, steel traders and building material dealers. Now as before, it sets high standards for the quality of its machines and systems, as well as for customer service.

Bamtec system for one-man operation

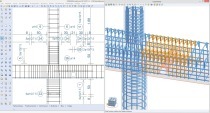

The Bamtec Evolution system is used for the manufacture of reinforcing elements and is based on the licensed system from the company Progress. It consists of a straightening and cutting unit for fully automated bar production from coil, as well as of a unit that welds the straightened bars to form a Bamtec reinforcing element.

The bars are further processed by a straightening and cutting unit. This unit features Progress Rotor straightening technology based on the company’s own feed units for every production line for wire transport, and on cutting units for every rotor. Wire diameter change takes place fully automatically by calling up the wire type selected in each case, with zero set-up time.

Cutting takes place electro-mechanically. Every production line is equipped with its own cut-off knife and its own electronic measuring equipment for initiating the cutting process. The bars manufactured in this manner are fed by a gripping and positioning unit to the welding unit. The individual steel wires are spot-welded together, randomly spaced, onto up to 10 steel belts. The system welds the bars to the installation belts at the calculated spacing and in this way manufactures a dimensionally accurate reinforcement element. Bars from 8 to 20 mm diameter are processed from coil in this manner. Thicker bars up to 36 mm are manually processed from round steel. Immediately following welding, the Bamtec element is coiled into a roll. The Bamtec system is designed to be operated by one man.

Minimum number of reinforcing elements

Installation of the Bamtec elements is quite simple as well. The rolled-up elements are transported to the construction site and are there moved by crane to the starting positions. Installation is extremely accelerated and simplified by the minimum number of reinforcing elements and rapid unrolling. This can also lead to reduction in overall construction time. The reinforcement layers are manufactured individually for the individual layouts and loading situations, on a just-in-time basis. With the Bamtec software, the position, length and all bar diameters for the required elements are calculated in advance. Blockouts and additional bars can be taken into consideration as well. This results in optimal use of material and in savings in reinforcing steel.

BAM AG comes to a very positive conclusion about its partnership with Progress. “Following the announcement of the change to Progress Maschinen & Automation, we were able to present the newly developed Bamtec Evolution system only 15 months later: a milestone in Bamtec reinforcement technology,” as summarized by Franz Häussler, Managing Director of BAM AG.