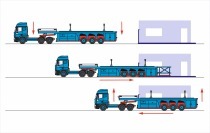

R-Tech loading/unloading systems – new load-dropping pallet

R-Tech, the company based in Willendorf-Strelzhof in Austria, has been manufacturing transport racks for the precast concrete industry since 1998. R-Tech entered the load-dropping pallet it developed in 2016-2017 in its bid for the 2018 Innovation Prize for the Supplier Industry for Concrete Components. The pallet was developed for transporting precast wall elements, lightweight wall elements, and wooden wall elements, and is thus suitable for a wide range of applications. It is also in line with the trend for the use of lightweight construction elements in precast construction, of which R-Tech has taken note.

The newly developed load-dropping pallets are characterized by the following features: the wall elements to be transported are held in place by sliding components or by drilled rails. The guide shaft integrated into the transport rack considerably facilitates picking up the pallets, even when visibility conditions are poor – an advantage over load-dropping pallets with twist-lock systems.

Tilt-tested

The plug-in stanchion system enables erection of a barrier wall in the middle of the pallet and, at the same time, stanchions can be used on the outside to ensure stability of the transported elements. All dimensions have been matched to already existing product developments. These design types have been tested by indepen-dent certified structural engineering firms and subjected in practice to tilting tests (//www.baumagazin.eu/kipptest-sicherheit" target="_blank" >www.baumagazin.eu/kipptest-sicherheit:www.baumagazin.eu/kipptest-sicherheit/).

In its submission for the 2018 Innovation Prize of the Supplier Industry for Concrete Components, R-Tech provides reference customers who already use the new unloading pallet – including the companies Oberdorfer, Maba, and Goldbeck.