Pumping technology for infrastructure projects worldwide

Upcrete technology allows for a smooth-running production of complex and volumetric precast concrete elements as well as precast elements with structured surfaces of high quality. The technology facilitates the manufacturing process and reduces crane capacities. Three examples from Australia, China and Ireland.

Upcrete technology, developed by Ratec, has established itself in recent years as a modern and effective solution in order to produce particularly complex and structured flat or volumetric concrete elements. The core of upcrete is the special pump technology with the support of the UPP100 concrete pump, which has been continually developed and optimized for various applications in numerous projects and trials.

Often, the use of the UPP100 is a result of occurring challenges due to special formwork restrictions or complex element details.

Optimum adjustment of the filling pressure

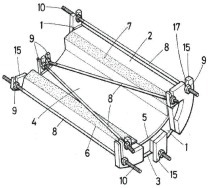

By pumping concrete from below into the mold, the air is pressed upwards out of the mold and air inclusions in the concrete are virtually excluded. A significant advantage of the UPP 100 is its design as a rotor pump. This allows precise and fine metering of the concrete supply and optimum adjustment of the filling pressure. One of the essential differences to common piston pumps, is that they work with a rather jerky pressure. This carries the risk of possible mold deformation and can lead to the displacement of not firmly fixed inserts, such as corrugated pipes. As a result, the element would be useless, leading to an unnecessary amount of effort.

The three current examples, described below, give an outline of different fields of application.

Sky Rail, Melbourne

In Melbourne, in the Southwest of Australia, a „Sky Rail“ line is constructed to relieve the city‘s traffic situation. The pylons for the new elevated railway line are produced using upcrete pumping technology.

In February 2017, the first of the approximately 350 pylons were installed. By November 2018, the construction work should be completed. While the project caused controversy with affected residents, the technical implementation of the column elements also posed a challenge to the precast production.

To produce the elements with different heights, the customer uses molds, which can be adapted to the different heights by means of a movable floor. As a result, the filling through the sides of the mold is not possible. In addition, there are complex recesses on the upper element side, so that a filling from the top is also unfeasible.

Even filling and optimal spreading of the concrete

Ratec had previously developed a concrete filling connection that can be used in the bottom formwork. In order to realize different element heights, the distances between concrete filling connection and raised floor formwork are bypassed by PVC pipes. The concrete supply with the UPP100 ensures even filling and optimal spreading of the concrete within the formwork. Self-compacting concrete was used in this case, but this is not a requirement for using the pump. A flowable and pumpable concrete and a pressure resistant mold are sufficient.

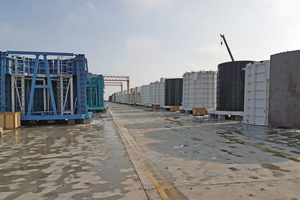

Another example for prefabrication with a UPP pump station at the construction site are wind parks that are currently being built in Western China with the help of upcrete technology.

Modern wind power plants – built with Upcrete technology

The customer Jinke New Energy develops and operates facilities to generate renewable energies like wind power, photovoltaics, solar thermal, biomass and other alternative sources and is one of the leading suppliers of the country.

The company’s current wind power project in Hami includes two production sites for erecting 100 around 120 m high concrete towers for 2 MW wind turbines type HZ111 and GW115. Due to the fact, that at the current location the strongest winds occur at about 120 m height, it was necessary to convert construction to prefabricated concrete elements, in opposition to steel construction – the traditionally used method – where masts up to a height of 90 m can be implemented technically and economically feasible.

Each mast consists of 30 reinforced concrete elements. The lower 18 sections are produced as semi-circular elements, the upper twelve as complete circular elements.

The main challenges for the customer were in particular: efficient filling of the approximately 200 molds per production site; very tight reinforcement of the elements, which makes it difficult to fill from the top; desired reduction of crane use and time gain; optimization of surface quality.

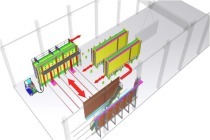

Filling connection for closed molds

First, a suitable concrete filling connection was developed. With a diameter of 125 mm, this newly developed inlet can be used without any problems anywhere, where molds are filled using a standard piston pump, which typically has a hose diameter of 125 mm.

In the next step the customer chose to also use upcrete pumping technology and installed the UPP100 pump station at both production sites. The pumps were delivered with a special transport trolley, which ensures smooth logistics on site. The concrete is supplied by a transport mixer, which is directly coupled to the pump and makes the use of a concrete bucket unnecessary. Thus, the desire for a reduction of crane capacity could be fulfilled.

The project demonstrates that upcrete technology can be easily integrated into an existing project without interfering with the production processes and at the same time leads to an increase in element quality and process optimization. In particular, the newly developed concrete filling connection UCI (Universal concrete inlet) could be interesting for projects where piston pumps are used to fill closed molds.

Optimization for culvert elements production in Europe

In Ireland, upcrete pumping technology is currently being used for the production of precast concrete box culverts. The elements are used as a conduit to enclose small roads, pathways or flowing water beneath roads, railways or embankments. With modern and automated production, the customer, as one of the largest manufacturers in the country, produces more than 60 m of culverts per day. Upcrete technology was considered to solve the problem, that air voids occurred on the inner wall surface of the elements. This bears the risk of corrosion on the reinforcement steel, which in the long term impairs the carrying capacity of the element.

So far, the problem was solved with high efforts in finishing works. Now, a more economically efficient solution should be found to increase surface quality in production. Furthermore, the filling of the molds with a concrete bucket took up too much crane capacity and should also be reduced with an alternative filling approach. With the use of the UPP100 the desired goals could be achieved. First tests already showed, that the surface quality of the elements was significantly improved. The UPP is tailored for use in precast concrete plants and, depending on the production concept, can be integrated very well into existing processes. For this purpose, the pumping station can also be designed as a mobile solution. In the current application, the customer provided a chassis for the pump.

Suitable for all pumpable concrete mixtures

The recent project examples show the various benefits of using upcrete pumping technology. A UPP pump station can be used both in a factory and on the construction site. The suitability of the mold for pressure-filling is checked in advance by Ratec, and is – in most cases - not an obstacle. A special concrete filling connection ensures that the formwork finish on the element is smooth. The pump is suitable for self-compacting concrete as well as for all other pumpable concrete mixtures. Pump wagon and accessories for hose handling make it possible to provide very mobile solutions. The focus is on the smooth integration into the customer‘s existing production proc-esses. The main arguments for the use of upcrete pumping technology are the improvement of surface quality, optimization of production processes and reduction of crane capacities.