(11) EP 2 559 824 A1

(22) 27.12.2002

(43) 20.02.2013

(71) ANCHOR WALL SYSTEMS, INC. Minnetonka, MN 55345-5996 (US)

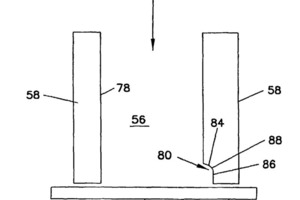

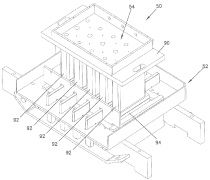

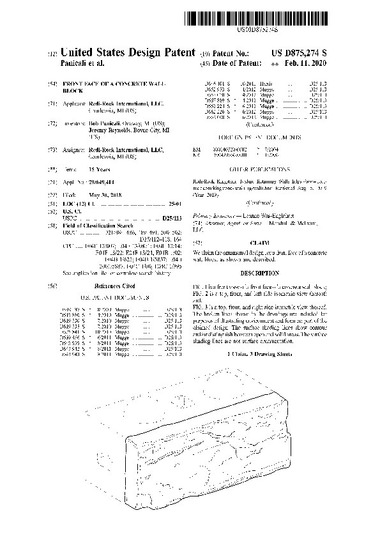

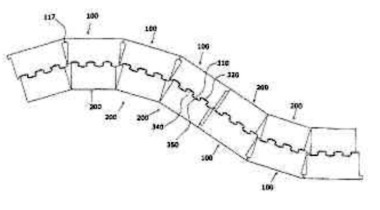

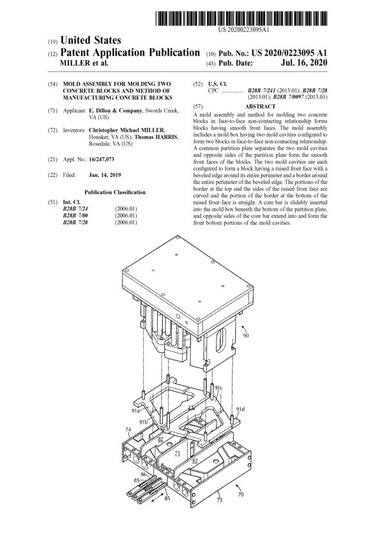

(57) Molds and processes that permit high-speed, mass production of retaining wall blocks having patterned or other processed front faces, as well as retaining wall blocks formed by such processes. The invention permits the front face (12) of the block (10) to be impressed with a pattern or otherwise directly processed, to allow the formation of pre-determined block front faces, while at the same time facilitating high-speed, high-volume production of blocks (10). Pre-determined front...