New thermal power plant for greater climate protection

Vattenfall aims for fossil-free energy generation within one generation. In Berlin, the locations of the power plants play a central role. An important building block towards the climate neutrality aimed for is the gas and steam turbine power plant in Marzahn, taken into operation in 2020. The company Porr, commissioned by Siemens AG, provided in Berlin the foundations for one of Europe’s most modern thermal power plants.

The HKW Marzahn thermal power plant currently supplies 150,000 households with district heat and power, contributing to reduction of CO2 emissions. Porr supported the project by carrying out the main construction works and erected, in addition, four turnkey high-rise buildings.

Reliable execution

The contract for the main construction works for the power plant and the erection of four turnkey utilities buildings was awarded to the company Porr Ingenieurbau. The motivation for realizing this challenging individual project was high: this project would superbly put to the test the comprehensive competence of Porr as technology leader for construction of demanding, individual projects with its own experts.

The main construction works included earthworks, several utility lines, the foundations for the so-called Power Block, two stair towers of 45 m height, two turbine tables, one switching station building, additional auxiliary buildings, and road construction. Added to these were planning and turnkey implementation of a unit control room building, an administrative building; a social, storage and workshop building.

Porr’s logistic masterpiece

The heart of the entire plant is the Power Block. It houses the two engine houses for the turbines, two transformer buildings, the boiler house, the feed-water pump house and the switching station building. Owing to the ambitious time schedule, planning of the supporting construction works and the numerous sub-contractors working in parallel in this area presented a considerable logistic challenge from the very beginning.

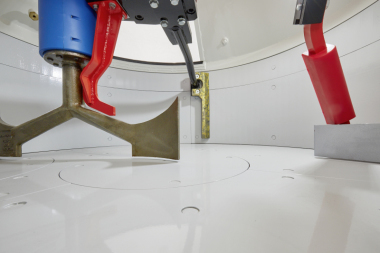

Complex turbine table and staircases

Aside from the construction logistics – in particular, the turbine table of the steam turbine – turned out to be a challenge. Supported on six vibration dampers at a height of 15 m, it is the supporting body for the turbine and the associated generator. For concreting, a temporary scaffolding was erected between the column-and-beam construction. This auxiliary construction provided the support for a total of 45 tons of reinforcing steel, 170 embedded parts and 280 m³ of concrete. The high degree of reinforcement and the installation tolerances of 10 mm for formwork and embedded parts required maximum concentration in laying the reinforcement.

Turnkey buildings

In addition to the work on the power plant, Porr was also responsible for turnkey construction of the unit control room building, the administrative building; the social, storage and workshop building; as well as the garage building. The power plant, once in operation, will be monitored and controlled from the unit control room building. For this purpose, the workplaces arranged in an oval configuration are connected with the server room via a raised floor system. In the social, storage and workshop building, spare parts are managed, plant components serviced and hazardous materials stored. For these purposes, a crane was installed in the machine hall.

Successful completion of the entire project

Since the start of construction in September 2017, Porr processed around 20,000 m³ of concrete, 2,000 tons of reinforcing steel and 15,000 m of piping in the area of the Power Block and the auxiliary buildings, providing in this way not only the proverbial foundation for the power plant. In February 2019, the major works were successfully completed and handed over to the client. In addition to the outdoor facilities, the Porr team carried out the interior construction work, fire protection installation and road construction.