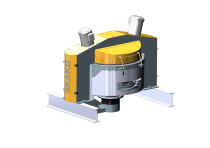

New ring-pan mixer for highest concrete qualities

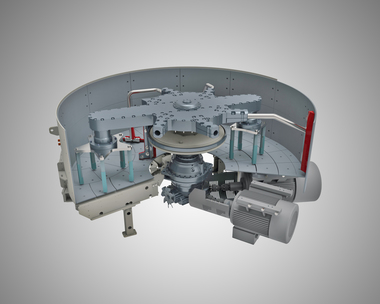

Ring-pan mixers from Liebherr have been successfully in operation in concrete plants for many years worldwide. The new RIV 2.5 D ring-pan mixer raises the standards for production of high-quality concrete mix still higher. The advantage of all Liebherr ring-pan mixer systems is the ring-trough system. The special form of the ring canal guarantees that the complete mix is forced to flow to the mixing paddles or tools and is completely homogenized very rapidly. The mix cannot avoid from the tools.

New is the infinitely adjustable speed of the double-whirler system, independent of the main drive. Two high-performance electric motors drive agitator and whirler system mechanically independent from each other. The advantage is that the speeds of the tools can be optimally adjusted, depending on the progress of the mixing process. The two whirler tools are fixed to the main agitator at different distances, guaranteeing quick and optimal mixing in all areas. The whirler tools ensure, moreover, perfect bonding of the cement paste. High whirler speeds prevent lump formation. The rotational speeds can be changed and adjusted to a given mix design during mixing by means of the frequency converter. In this way, different rotational speeds can be selected during the filling process for dry and wet mixing as well as during discharge. Even regulation depending on the effective power of the motor is possible. This satisfies all requirements, in particular for production of special concretes, according to the manufacturer.

Open construction has tremendous advantages

The wide-open trough allows optimal material feed and free access to the mixing tools for all ring-pan mixers, including the new RIV 2.5 D. This type of construction moreover allows quick and thorough cleaning. The generously designed mixer cover, free from overhead attachments, makes it possible to open the mixer, depending on the application, between 30 % and 60 %. This ensures easy access from above and, accordingly, easy maintenance. The gear and the drive motors are arranged below the mixer and are easily accessible. This leaves sufficient room for the components required for material feed and dedusting on the upper side.

Liebher, drawing on its great experience potential, can offer both innovative mixer systems and complete mixing plants for concrete production. The new RIV 2.5 D mixer system can be ordered at the Bauma in April 2016.