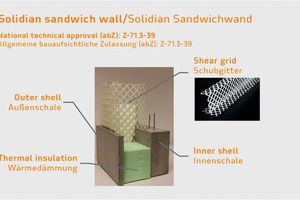

National technical approval granted for sandwich façade wall made of textile-reinforced concrete

A Solidian system with national technical approval is now available for the construction of sandwich walls with textile reinforcement. Hence, the team of engineers of the Albstadt-based specialist in carbon and AR glass reinforcement has successfully developed a system opening the market for smooth application of a new technology in wall and façade construction for the entire construction industry.

Several pilot projects of the last few years have revealed that non-metallic reinforcements provide clear economic advantages, while allowing for a much more flexible construction method. Now, the technology breaks its way across the full breadth of the market because the use of textile-reinforced concrete is considerably simplified in terms of building law due to the national technical approval granted for the innovative façade wall.

Excellent life cycle assessment

The arguments in favor of the use are emphatically confirmed by the following figures: The thinner design allows architectural concrete savings of up to 70 %, entailing even several effects – the material costs are declining and more space is created; in particular, in case of construction abutting property lines more usable and rentable floor space can be created within the building.

“In respect of life cycle assessment, textile-reinforced concrete defeats the traditional construction with steel by far,” says Solidian General Manager Roland Karle. “Concrete, production and transport costs are significantly lower and maintenance costs are avoided in the long run, because textile-reinforced concrete does not corrode and a long service life is guaranteed.”

Setting new standards

The “Eastsite” office complex built by B.A.U. property developer in Mannheim-Neuostheim proved to be a predestinated project for the use of textile reinforcement. It is regarded as ground-breaking for modern corporate architecture. So, investor, architect and contractor, together with Solidian, showed the necessary pioneering spirit and, for the first time, used textile reinforcement for the façade design in the realization of the Eastsite VIII office building.

“Fischer Architekten, Dreßler Bau and Solidian have jointly implemented the new sandwich technology for two Eastsite buildings with approvals in the individual case, so that we are now very pleased about the national technical approval for our sandwich façades,” says Solidian General Manager Karle.