Fully bonded waterproofing systems –

Options and limitations

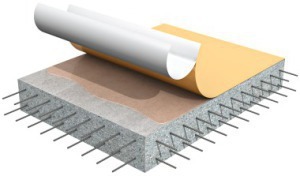

Fully bonded waterproofing systems are mainly used for sealing

basements and other underground concrete structures designed for high-grade use against groundwater ingress. This technology was used for the first time in 2005 on a construction site in Germany. Although this method has not yet become generally accepted engineering

practice, over 700,000 m² are currently installed per year applying this technology, and this number continues to grow steadily. The innovative

aspect of a fully bonded waterproofing system is that it intends to achieve a higher safety level by taking advantage of the waterproof concrete construction method and combining it with crack bridging, resistance against water penetration under pressure, and prevention of water migration and tracking. In construction practice, this method has become a tried-and-tested solution; it is also referred to in the pertinent literature as well as in the future DBV Code of Practice, which is currently being prepared. The main benefit for the client is that the basement of the building will be dry and safe to use from day one. As with any waterproof concrete structure, the successful implementation of this waterproofing concept will heavily depend on a professional design approach that considers the concrete construction

method as well as the fully bonded waterproofing technology

and all its details to be a complete and coherent system. At this stage, it is also necessary to define clearly worded requirements that the system has to meet. In addition, care must be taken to ensure that the installation of the waterproofing system is executed to a high standard of workmanship and subjected to a thorough on-site quality

control process.

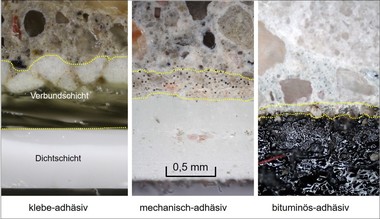

In practice, it is often heavily debated whether the use of a fully bonded waterproofing system actually makes sense and which aspects to consider in this context. This is why this lecture will critically review recent experience gained in applying this new construction method while also giving an outlook regarding future codes and standards. Particular emphasis will be put on discussing the question

of where and to what extent this technology would add value compared

to established construction methods, such as the waterproof concrete construction method or bituminous waterproofing.