Formwork handling on stationary production lines

The company Fabcon Precast, based in the USA, is a manufacturer of prestressed façade panels, primarily executed as sandwich construction. For its production facility in Kansas, the company invested in a completely new formwork system and in innovative handling of formwork from the German manufacturer Weckenmann Anlagentechnik GmbH & Co. KG.

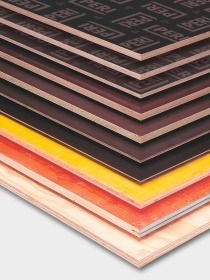

The principal element of the formwork system consists of form profiles with switchable magnets, with which high-quality panels of up to 305 mm thickness are manufactured. The system is used on stationary production lines. Production systems with stationary production lines, compared to circulation systems, have the disadvantage that a number of production processes are less suitable for enhancing production efficiency.

Rapid stripping, cleaning and oiling

Fabcon had set Weckenmann the task of developing a process and/or a machine to eliminate this disadvantage, at least in part. The result was a machine with which stripping, cleaning and oiling of the form profiles could be easily managed by only two persons.

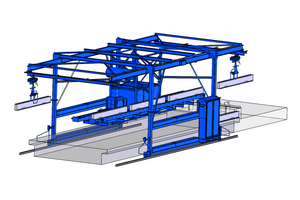

The machine is fitted with two handling cranes, a formwork cleaner-oiler and transport lines. The procedure is as follows: the first operator picks up one formwork from the pallet with the handling crane and sets it down on one of the transport lines, which conveys it to the formwork cleaner-oiler. At the other end, the formwork is picked up, also by a handling crane, by the second operator and immediately again placed on the line. The machine travels, floor-bound on tracks, and proceeds continuously along the production line.

Intermediate storage in a magazine on the machine, is a possible extension. Fabcon Precast benefits from this investment with clean and oiled formwork and notable savings in worktime.