Flexible mesh production at Holterman Wapeningsstaal

Eurobend GmbH offers solutions for every precast company, regardless of size and application, with innovative and well-established machines for the production of standard and customized precast elements and wall panel reinforcements.

The Eurobend machines, equipped with high-technology features, sophisticated electronics, computer software and hardware with a unique redundant memory system for eliminating the possibility of production downtimes due to hard disk defects or data losses and an interface for exchanging production data using various industrial formats (such as “BVBS”, “Unitechnik”, etc.) are easy to operate and due to the thoughtful modular design easy to maintain.

The recent installation that took place at Holterman Wapeningsstaal BV in Markelo near Amsterdam, the Netherlands, includes a flexible mesh welding line of the PL XY series together with a rotor straightening and cutting machine of the MELC Flexi series and a lattice girder machine of the PL TRIS series.

The PL X-Y series

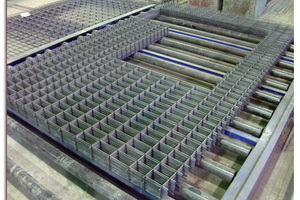

The production of standard, customized mesh and special mesh with openings is now covered for Holterman Wapeningsstaal BV, by the unique high-end CNC programmable mesh welding line PL XY Twin working from pre-cut bars (patented).

It produces mesh with maximum diameters of up to 16mm for both line and cross wires. The PL XY is equipped with two multi-point moving welding blocks, achieving up to 400 welding points per min. Any mesh can be produced instantly, one type after the other, without any adjustments, as everything is controlled by the machine’s computer program.

The line wires are fed manually into pre-selected grippers who are mounted on a carrier. The carrier inserts automatically the line wires into the welding machine and returns to the start-up position for reloading, while the machine welds the mesh. Each gripper is equipped with a LED light indicator, facilitating the line-wire feeding. This system eliminates practically the idle time between two meshes produced.

A secondary feeding system on the line wire carrier enables the production of mesh with variable line wire lengths within the same (material saving mesh) or mesh with openings.

The cross wires are fed into the welding line automatically from a cross wire feeder. A secondary cross wire feeding and positioning system enables the production of mesh with variable cross wire lengths and mesh with openings. In this case, a second auxiliary display facilitates the feeding of the special cross wire lengths.

The produced mesh is removed automatically through a mesh stacking and roller conveyor system.

Mesh preparation – production of the pre-cut bars

In addition to the existing large number of single and multiline rotor straightening and cutting machines, type MELC Monoline and MELC Polyline, Holterman Wapeningsstaal BV choose again another MELC rotor straightening and cutting machine to accompany the new PL XY mesh welding line and produce all bars required by the welder. Placed next to the new PL XY mesh welding line, an independently operated multi rotor straightening and cutting machine of the MELC Flexiline series using Eurobend’s 4G rotor with hyperbolically profiled rollers and our patented convergence guiding system ensure perfect straightening and length accuracies. All diameter changes are achieved in 2 to 3 s without any moving mechanical parts, producing ‘just-in-time’ or according to the day’s production schedule the needed pre-cut bars in the requested diameters.

The extremely fast diameter changing system offers the unique possibility to produce one after the other the pre-cut bars for each mesh in a batch.

Thus, the material handling, storage and logistics issues are simplified guaranteeing personnel and investment savings.

The combination of the unmatched flexibility offered by the PL XY Twin welding machine, together with the straightening superiority and the diameter changes within seconds of the MELC Flexiline rotor straightening and cutting machine, is the most efficient and flexible solution for Holterman Wapeningsstaal BV for their production of standard and customized mesh and mesh with openings for all their precast customers.

Mesh preparation – production of lattice girders

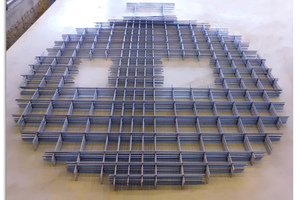

The “PL-TRIS” series of lattice girder welding lines installed at Holterman Wapeningsstaal BV can produce most types and sizes of lattice girders and offers reliable and cost-effective production. This is a high output machine version, as it features ‘double welding step’ and it is equipped with powered de-coiling stations for line and diagonal wires with tension detector and wire loop accumulators, ensuring always smooth and accurate feeding of wires.

Each straightening section for both line and cross wires employs advanced, easily adjustable roller straightening devices with patented product self-leveling anti-twist rollers.

The unique double-step continuous bending system, with retractable bending pins for the two diagonal wires, ensures accurate and consistent operation.

Our flexible welding head design and electrically-driven height adjustment mechanism ensure accurate production of various lattice girder sizes. A set of hydraulic clamping units, mounted on a servomotor-driven carrier, ensures also accurate feeding of wires during the production process. The high speed cutting operation together with the synchronized and fully automatic stacking and batch removal guarantee the continuous production of high quality lattice girders.