Abilys SB 2.0 – The smart board for precast machinery

Vibrating block machines require particular attention because their appropriate operation determines the productivity of the entire plant. During production, anomalies may occur on concrete products. Understanding the causes of such anomalies is usually complex since a product defect or deficiency can be due to a number of malfunctions, including issues encountered on vibrators, decks, silent blocks, drill, stops etc. Many points have to be checked, which makes conclusions difficult to establish and thus delays the resumption of the production process.

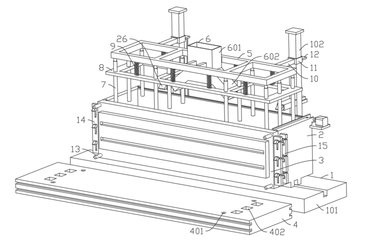

Abilys is a smart board equipped with sensors that can easily diagnose the behavior of the press block machine during production. The Abilys board is inserted in the machine without stopping the production. It can check all the production steps by scanning movements, vibrations, and defects through a real-time record of more than 400 physical datasets per second. The analysis of the recorded data during the production cycle makes it possible to see each step of the casting process, the surface distribution of the mold clamping, when and how the drawer arrives on the mold, the distribution and efficiency of the filling vibration, how the drill compacts the products, how the final vibration step works, and, lastly, the mass distribution of the cast products. Abilys diagnostics permit the optimization of the machine control parameters and allow for easy preventive or corrective actions.

To date, this patented technology has proved its efficiency on more than 100 press block machines installed in French precast plants. Its use led to an average gain of about 10 % on the production cycle, and production waste was reduced from an initial level of 3-5 % to 1 %.

The analysis of the results led to a better understanding of the causes of several defaults. Thus, the production efficiency could be increased by improving the machine parameters and the consistency of product quality. Consequently, reducing the consumption of cement and the CO2 impact becomes easy to manage.

Another advantage of Abilys is that this technology can record a reference point for the appropriate operation of the machine, thus facilitating future diagnostics. The Abilys technology is also used for the technical handover and acceptance of new installations and for the qualification of the performance of new boards.