Silo safety at last – the Shield Lite fail-safe silo protection system

Overpressurization incidents regularly occur when filling storage silos from tanker trucks, but many of them go unnoticed. However, each such incident poses a significant hazard to people, the system, and the environment. Overpressurization can cause the silo to burst, the filter unit to fall from the silo roof, or material to spill into the environment. This can result in fines and the revocation of operating permits. Even worse, it can cause lost-time injuries or fatalities among operating staff. This is where the full responsibility of health and safety officers and plant managers lies.

Appropriate silo protection equipment reduces or eliminates this risk. To achieve this, the full functionality of the silo safety system must always be ensured. Such equipment often includes inexpensive components that are not fail-safe. Failure of or tampering with the safety equipment can only be detected during an inspection by a competent person, which is time-consuming and costly while also involving the risk of working at height. In addition, inspections are usually not conducted prior to each filling process. As a result, there is no certainty that the safety components will work properly during silo filling.

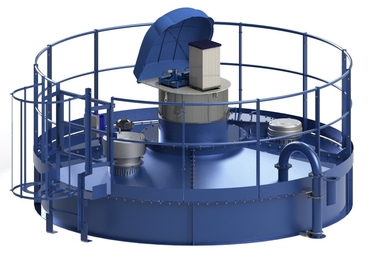

Envea’s Shield Lite system provides this certainty because this unique, fail-safe silo protection system tests all safety-relevant components before each filling process, and filling can start only if they are all fully functional. The Shield Lite silo protection system includes a fail-safe pressure relief valve, a patented fail-safe pressure sensor, a fail-safe level sensor, and a fail-safe inlet shut-off valve, as well as the control system, i.e., the ground level test panel at the filling point. The fail-safe protective components cannot be tampered with. In the event of technical failure or human error, they will not allow the silo to be filled until the problem has been resolved.