Resource-saving construction with lightweight & infra-lightweight concrete – CO₂ absorption by lightweight concretes

The careful use of natural resources is a central concern of our time and is considered an essential element of decarbonizing cement and concrete. In order to achieve this goal, it is necessary to expand existing material loops and to establish new recycling strategies. It is therefore of vital importance to develop concepts for tapping the potential for savings in carbon emissions of the different products of the cement and concrete industries. Possible approaches include the development of low-emission lightweight concretes through the use of recycled lightweight aggregates and by exploiting the carbonation potential of lightweight concretes.

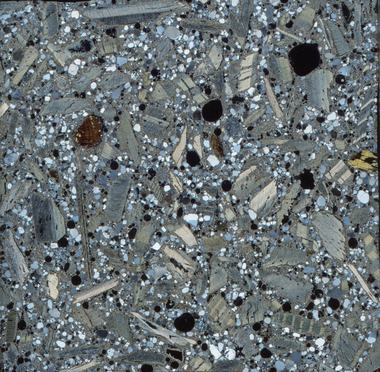

Depending on the characteristic properties of the recycled components, they can be reused as lightweight aggregates in different types of lightweight concrete. This requires determining the properties of the recycled components and verifying their performance in terms of fresh and hardened concrete properties in experimental tests. For this purpose, parameters such as the density and water absorption of the recycled components are examined and then used in an optimized mix design to reproduce the same type of concrete as that in which the recycled components were originally used. This concept is exemplified by infra-lightweight concrete (ILC), which represents the most recent development stage of lightweight concrete for use in monolithic exterior walls. Optimizing the balance between reduced density, sufficient strength and the lowest possible thermal conductivity, ILC offers a competitive alternative to the conventional multi-layer wall structures.

Additional carbon saving potentials for the life cycle analyses of lightweight concretes can be tapped by taking recarbonation into account. Possible carbon retention rates and the resulting carbon saving potentials of no-fines lightweight concrete blocks and recycled products made of lightweight concretes will be shown as examples.