Biomass-based lightweight structural concrete – A route towards carbon-neutral concrete construction?

According to the Global Climate Report, we will not be able to reach our climate targets without carbon sinks. It is thus foreseeable that prices of carbon certificates will increase significantly. A carbon and sustainability surcharge is already levied on the purchase of fresh concrete. Thus, the construction industry aims to implement carbon-neutral concrete production in the coming decades.

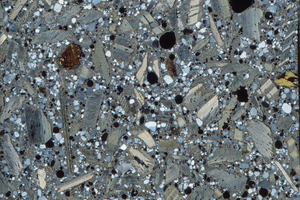

Together with Cemwood, an industry partner, the Institute of Construction Materials (IWB) at the University of Stuttgart is exploring options and potentials for carbon capture and storage (CCS) to sequester carbon in concrete over the building life cycle. To achieve this goal, the IWB adds as large a volume of plant-based solids as possible to the fresh concrete to substitute specific mineral aggregate sizes. Once the concrete has hardened, the embodied carbon is permanently stored in the concrete matrix.

The higher the proportion of sequestered carbon, the faster the concrete will become carbon-neutral, or even carbon-negative. Rather than storing carbon in the soil, wood particles are used to sequester the greenhouse gas in the concrete structure. However, carbon-neutral concrete requires the use of such particles in large quantities. Therefore, alternatives to spruce wood were sought that would be available at a large scale to protect local forests. Fast-growing tree species such as birch and paulownia (kiri wood) were chosen. The latter is grown in Germany as short-rotation coppice, which can be harvested every three to five years. The two partners are currently investigating concrete mix designs suitable for achieving robust workability characteristics of the fresh concrete on the one hand and high performance of the wood concretes on the other. In addition, they seek to identify environmentally friendly binder mixes with minimal clinker content.

This paper presents the current state of research and the process steps for producing a homogeneous concrete mix for strength classes up to LC30/C37.