Reducing the material consumption of flat floor slabs

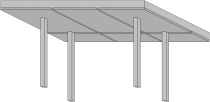

Over the years, the development of reinforced-concrete floors for multi-story building construction has given rise to a large number of different designs. When reinforced-concrete construction was still in its infancy, the main aim was to minimize material consumption. This is why floors for building construction were designed as distributed-support structures composed of primary and secondary floor beams (see F. Hennebique 1895). In the following period, efforts were mainly geared towards reducing labor costs, which is why the use of flat floors became more widespread (see R. Maillart).

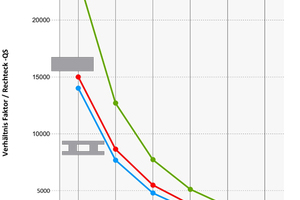

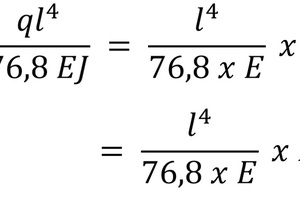

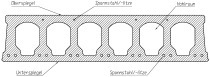

Nowadays, the aim is to fully utilize the benefits of flat floors, such as their low height and smooth underside, while reducing material consumption owing to resource scarcity. This goal can be achieved only by combining prestressing with a hollow-core cross-section and prefabrication of floor slabs. A sandwich cross-section is the only option for achieving maximum material efficiency, which can be demonstrated by identifying the influence of different cross-sectional shapes on the deflection behavior of floor strips because the ratio of own weight to cross-sectional rigidity will determine the magnitude of deflection:

The sandwich cross-section shows the best performance in this regard.

However, the only option for producing sandwich floor slabs cost-effectively is to resort to prefabrication, but this method partially loses the slab’s isotropic material characteristics since the structural detailing of the flat floor needs to be aligned with the orthotropic material behavior. The floor slabs predominantly show a uniaxial pattern and transfer the loads acting on them to a column strip designed with identical dimensions. At the same time, the end zones of the prefabricated floor slabs provide the integrated formwork with the shear reinforcement required for the column strip. Furthermore, the column strip is subjected to prestressing in order to keep the total deflection of the flat floor as low as possible.