Automated manufacturing of modular carbon-reinforced ribbed concrete floors

Ribbed floors provide a promising approach for significant material savings compared to conventional reinforced-concrete flat slabs. This article discusses a flow manufacturing process that uses 3D-printing technologies of concrete and automated integration of reinforcement to produce material-optimized floor modules. The structure of the modules is optimized for different load scenarios. Digital manufacturing processes make it possible to place the concrete without formwork while providing a high degree of design freedom.

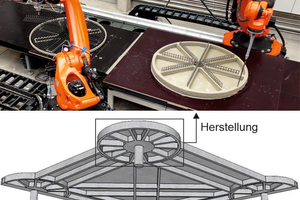

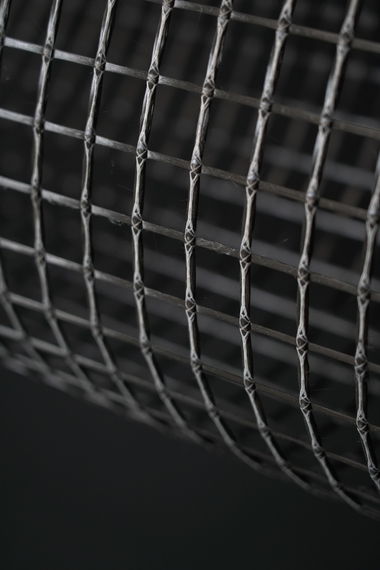

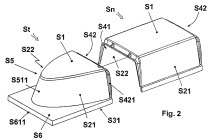

The individual floor modules consist of thin cast plates onto which bidirectional ribs are printed along the principal stress trajectories. The manufacturing process includes several robotic work steps that ensure high speed and reliability of execution. In the first step, a robot inserts carbon reinforcement into a 3D-printed concrete contour that functions as permanent formwork for the floor plate. In addition to the extensive flexural reinforcement, a T-shaped carbon shear reinforcement is integrated to connect the concrete ribs. Once the plate is poured, the ribs are extruded along the shear reinforcement protruding from the plate. Using external tendons to assemble the modules manufactured in an additive process results in a modular floor system. The modules are dry-jointed, which allows for non-destructive deconstruction and reuse of the floor structure.