New channel material: concrete with basalt fibers

The Romans already knew the advantages of concrete. Today, modern building construction and civil engineering can no longer be imagined without this artificial stone. Hauraton now makes the construction material even more efficient for modern drainage material – with its innovative formula with natural basalt.

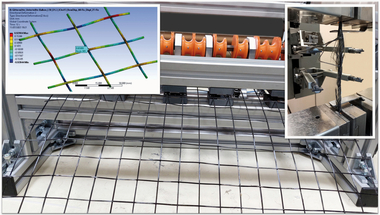

Concrete is able to resist high compressive stress, but only low tensile stress. For this reason, it has been continuously optimized over the centuries. In what is known as reinforced concrete, steel bars take up the tension in the tensile zones. In contrast, the addition of mineral or textile fibers increases, for example, green and edge strength and the resistance to cracking. For Hauraton, in particular, the latter is of great significance: because the higher the resistance to cracking, the more robust and longer the service life of the product. This is especially important for construction components subjected to considerable dynamic loads. This is the case, for example, for drainage channels that are at times subjected to vehicles traveling at high speeds or that are regularly subjected to high loads. For this reason, Hauraton, as one of the pace-setting market leaders, is continuously active in research and development for optimization of construction material.

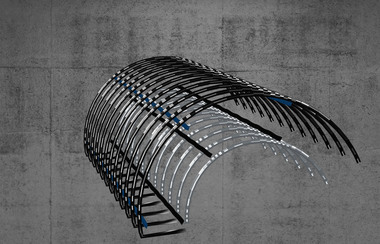

Concrete as channel construction material – a new era begins

Hauraton has now rung in a new era in concrete production, according to the supplier. The addition of basalt fibers not only creates a construction material with long service life, but also one that is on a 100 % natural basis. The basis, basalt rock, is common all over the world. It is available in large quantities and is daily formed anew on our earth. When basalt rock is liquefied, various kinds of fibers with impressive properties can be made from it. Interaction with the universally-known material concrete, increases both the serviceability and service life of products. For Faserfix drainage systems, which are made from fiber-reinforced concrete, the use of basalt fibers now brings many advantages.

Natural product with a better eco balance

Basalt fibers revolutionize the construction material concrete, because they offer many advantages. The crucial benefit: The fibers of the effusive volcanic rock are a purely natural product for which no chemical changes in manufacture are necessary. Accordingly, while the sustainability factor is increased, the resources used in production decrease. In addition, with assumption of comparable concrete quality, the amount of cement can be significantly decreased – which positively affects the CO2 balance. All of the desired properties for the end product can be achieved with small quantities of fibers, thus leading to economical use.

Mineral mix easy to recycle

A further advantage, apart from economy of resources used and efficient production, is the ease with which the material can be recycled at the end of its product life. Since the end product is a purely mineral mix, there is no need for material separation prior to disposal. This greatly protects the environment. In addition, basalt fibers, based on the current state of science, do not generate fiber dust during processing or recycling, viewed critical by the WHO, that may cause long-term damage to the lung.

Strong and convincing properties

The properties of basalt fibers are outstanding. They resist temperatures of up to 800° C. They have high strength, and are likewise flexible, non-toxic, non-carcinogenic, resistant to alkali according to EN 14649 and ASTM C1666/C1666M and are UV stable. This enables applications for which other fibers cannot be used or that are excessively cost-intensive.

When comparing the effects achieved through addition of basalt with previously used fibers, it becomes clear: Basalt fibers make precast concrete elements even more dimensionally stable, ensuring high quality in this way. The durability of channel construction material is increased, since scaling of the surfaces, compared to the scaling that occurs on previously used concretes, is significantly delayed. Drainage systems made of basalt-fiber-reinforced concrete will therefore be much longer in use than is the case with other solutions today. At the same time, impact strength is noticeably increased, accompanied by reduced crack formation. Both the number of cracks and the crack width are reduced.

Mineral power particles

Both glass fibers and basalt fibers are minerals. Basalt fibers, in contrast to glass fibers, have a higher melting point, are more resistant to water, acid and alkalis – and exhibit more positive tensile and bending properties. All of this makes basalt fibers attractive in drainage technology as well as in numerous other applications in construction, energy and environmental engineering, among many others.

In view of more stringent climate targets today, energy consumption in production is another factor that definitely speaks for basalt fibers: Compared to other fibers, they have the smallest CO2 footprint. Conclusion by the manufacturer: anyone who wants to produce more resistant and durable concrete products – with cost effectiveness and economically and environmental benefits – will in future not get around basalt fibers.