CO2 reduction through machine-made reinforcement mats made of basalt fiber-reinforced polymer

As part of the “RebWeave” project, the universities of Aalen and Ulm are cooperating with Zweigart & Sawitzki GmbH & Co. KG and C-Con GmbH & Co. KG to develop a process suitable for the series production of high-strength reinforcement mats made of basalt fiber-reinforced polymer (BFRP). As the production of cement is an energy-intensive process, the construction industry is considered one of the biggest producers of greenhouse gas emissions. The use of non-metallic reinforcement elements in reinforced-concrete construction makes it possible to reduce the necessary concrete cross-sections and thus the required amounts of concrete, which saves resources and reduces carbon emissions.

When compared to conventional structural steel, BFRP offers advantages in terms of tensile strength, weight and corrosion resistance. In addition, its production is more cost-effective as well as energy-efficient and gentle on resources compared to carbon-based fiber composites. At the end of its life cycle, the BFRP-concrete composite can be recycled in an ecologically friendly process as separation of the individual components is eliminated.

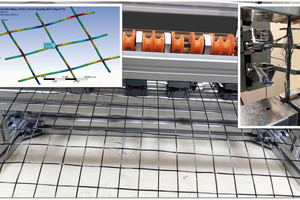

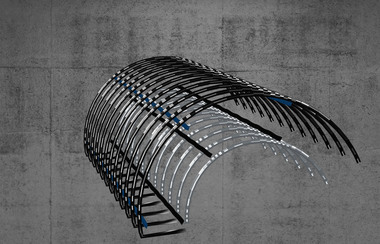

Woven structures of BFRP permit the production of dimensionally stable reinforcement mats. At the same time, the undulated structure is intended to improve bonding in the concrete, thus increasing the bond strength. The project is innovative in that it realizes the weaving technology while taking into account the mechanical properties of BFRP and scaling of the process. For this purpose, the production process is modeled in the form of a digital twin of the weaving machine.

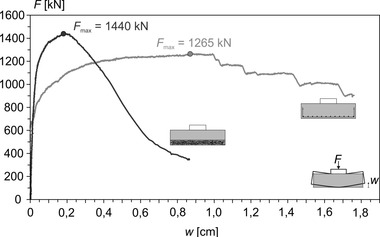

The required material parameters are established by mechanical

testing of the fiber composite bars under tensile and bending stress. It is apparent from the tests that the material behavior differs signifi-cantly from that of steel, which is explained based on the structural

make-up of these two classes of material. Initial test results of the material’s behavior in the concrete bond show the potential inherent in reinforcement mats made of BFRP.