Budova decided to invest in a new batching plant in the Odessa region

Budova is one of the largest construction companies in southern Ukraine and a recognized leader of residential house building in Odessa. In over 30 years of history, Budova has won the trust of thousands of Odessa families and built 60 properties, half of which are residential complexes. Major strategic directions of Budova activities are real estate building, apartment complexes, business centers, industrial facilities and realization of finished housing.

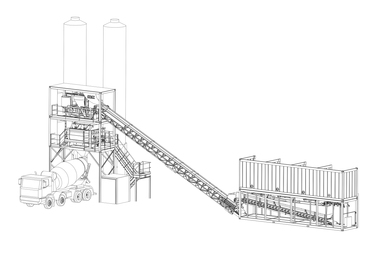

Budova building company has operated since 1990 and entered the number of leading multitask building companies of Ukraine, and it is an active member of the Building Academy of Ukraine. In 2018, Budova decided to invest in a new batching plant to produce high quality concrete for several construction sites in the Odessa region. When Budova purchasing department contacted the MCT Sales Manager Eng. Luca Cellini pointing out the special needs and requirements, he immediately proposed the MCT Italy Mobile Batching Plant type MCM. MCT mobile plant has been selected as the right solution in order to guarantee high production rate, save costs connected to transport / production time and it also meets all the local regulations.

MCM control unit very flexible

The main structure of this plant is composed of two 8 ft x 40 ft containers, which means it can easily be transported (by road, ship or train) from one site to another and is extremely easy to assemble. Transportation, installation and commissioning can be carried out by the customer‘s existing crew without the need for foundations, plumbing or electrical connections. The plant goes together using pinned connections with no needs for bolts and nuts that we call our “zero nuts and bolt” design. The two containers are connected to each other by four tapered pins positioned at the corners of the lower module, which are inserted and connected to the upper one: this provides stability to the entire structure.

The electrical and hydraulic connections are carried out and tested in the factory with the aim of guaranteeing maximum reliability of the whole system; the customer’s assembly crew are therefore required only to connect the industrial plugs from the motors to the control panel when the system is installed.

Furthermore, the innovative project with two 40’ containers, can be easily equipped with the integration of aggregate heating system, extremely important during the winter season in Ukraine. MCM 3.1.25 batching plant is also equipped with moisture, plasticity and water-cement ratio control systems providing uniform concrete that meets the requirements of UNI EN 206-1. The planetary mixer can batch high quality concrete of each consistency class (from 0 slump to self-compacting concrete), making the MCM control unit extremely flexible and suitable for any type of construction industry. The mixer capacity of 1500 liters water volume guarantees the production of 1 cubic meter of concrete each cycle and a total productivity of 45 cubic meters per hour.

Software is the heartbeat

The software is the heartbeat of the batching plant and guarantees the complete monitoring of the production processes, as well as the complete production report. The CompuNet system, developed by MCT Italy software department, consistently controls all the aspects of the production process and reports of raw material storage levels. All parameters are displayed in the control cabin touch screen, and the operator can easily monitor the process in real time. With MCT Italy remote assistance service, the MCT Engineers are able to monitor customer‘s production and provide immediate support in case of need.

“The mobile concrete mixing plant type MCM is confirmed as a winning solution; the innovative project that encloses the batching plant in two 40’ containers combines simplicity and quality, offering to the customer a unique solution in the international market. We are proud to have provided an advanced technological plant to a company renowned and esteemed as Budova. We are sure that the strong partnership between MCT Italy and Budova will continue in the near future with new projects,” states Eng. Luca Cellini, CIS Area Sales Director at MCT Italy.