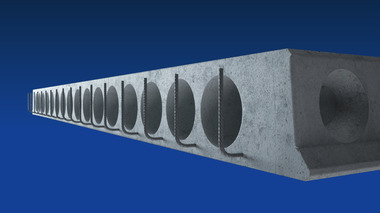

3,000 m² of hollow core floor slabs per week from Nastola

Plant manager, Juha Pulkkanen, states the production figures rather matter-of-factly, although they definitely sound quite impressing: 3,000 m² of just hollow core floor slabs are manufactured on four 140m-long production lines per week. In addition, ten prestressed mega girders with spans of more than 30 m each leave the factory of Nastola located on the southern edge of the Finnish sea district; they are complemented by wall elements, columns and TT slabs as well as some other structural precast concrete elements. In 2014, all this amounted to an annual output of 40,000 m³ of concrete manufactured on a floor space of 7,500 m².

Most of the customers are established in the South of Finland, in Greater Helsinki above all. In order to minimize the freight charges most of the basic materials such as cement (Cemex Finland), for example, are purchased from local suppliers. This adds up to daily quantities of 80 tons of cement and 10 to 12 trucks of aggregates.

Cooperation with Peikko as an important guarantee for success

Apart from the workforce of 60 committed people – working in two-shift operation – and modern plant equipment (mostly of domestic suppliers such as Elematic, Tuotetekno or Satateräs), this is even possible because of the short stripping times due to the high strength class C50/60 the company is using for a major part of the precast concrete elements. The twin-shaft batch mixer and the planetary mixer have been bought from German suppliers (Teka and BHS) some years ago.

According to Juha Pulkkanen, in particular, the good and trustful cooperation with Peikko, a leading Finish supplier of fastening and connection systems, has been bearing fruit for several years: “We are able to ensure our high standard of quality not least by consequently using Peikko elements for all relevant concrete components, starting with column shoes up to the large rebar couplers.” Petri Suur-Askola, Business Manager Precast Concrete Connections at Peikko, added in response to a question, with a smile on his face: “Of course, we are very pleased that Betonimestarit is not just any customer but may be called a kind of ‚fan‘, as even the conference table in Juha‘s office was made of a saw blade and the biggest available anchor bolt of Peikko.”

Text: Dipl.-Ing. (FH) Silvio Schade