161,000 m³ of structural concrete for wastewater treatment plant in Prague

The city of Prague invests about € 250 million, and is using up about 161,000 m³ of structural concrete, in a building project at the Imperial Island on the Vltava River. The central wastewater treatment plant is being modernized and extended. It is the only one of its kind in Europe; the structure is built completely underground. The requirements on the concrete structure are correspondingly high: sedimentation tanks must be permanently tight and the water quality must not be affected. Therefore, architects, planners and building contractors opt for spacers and sealing technology of Reuss-Seifert.

The capacity of the existing wastewater treatment plant is no longer sufficient for the Czech metropolitan city with its about 1.2 million inhabitants. Nitrogenous substances are insufficiently separated, the water quality is negatively affected. A modernization and extension was absolutely necessary in order to meet the stringent EU wastewater regulations.

Watertight and durable concrete structures

Since the end of 2015, the consortium comprising German and French construction companies has been building the central wastewater treatment plant in Prague featuring a capacity for 1.6 million inhabitants. The plant will be 600 m long and 130 m wide and will treat approx. 4.1 m³/s of waste water in normal operation, with a maximum of even up to 7.1 m³/s. The start of operation is scheduled for 2018.

Due to the fact that purification tanks must be watertight and durable, they are almost exclusively concrete structures nowadays. The thickness and quality of the concrete cover is a decisive factor in this regard. According to „Eurocode 2 / National Annex (NA)“ and the DBV Code of Practice on „concrete cover and reinforcement“, respectively, the reinforcement must be laid so that the finished structural component complies with the minimum concrete cover cmin assuring sufficient degree of safety. This requires spacers which ensure the proper concrete cover before and during concrete placement.

Spacers secure the concrete structure

Precondition: The products used may not impair the serviceability and durability of the structural component after concrete placement. In principle, they should have adequate load-bearing capacity and be resistant to physical, biological and chemical impacts.

Therefore, the architects, planners and building contractors selected spacers made of cast concrete and fiber-reinforced concrete from Reuss-Seifert. The spacers are used whenever the concrete structure has to meet particular requirements. They are approved in accordance with the DBV Code of Practice on „spacers“, resistant to thermal and chemical loads and provide for high strength additionally. As these spacers ensure a good bond with the freshly poured concrete, cracks affecting the water impermeability of the structure can be avoided or minimized at least.

Waterstops and bentonite strips used

Due to the fact that wastewater structures must permanently be reliable in function and watertight, professional sealing of the construction joints is highly important. For this purpose, Reuss-Seifert supplied several special products including Duxpa waterstops which ensure a strong bond with the concrete thanks to their mineral coating. Crystallizing substances close the construction joints by sintering, thus increasing the tightness. This reliably prevents an infiltration of the joint system, not requiring any protective membrane. The Duxpa waterstops can be installed independent of temperature and are therefore ideally suited to hot summers and cold winters in Prague.

In addition, Duxpa bentonite strips are used in the wastewater treatment plant. The expanding waterstop closes the joint through contact pressure, thus sealing the joint reliably. Moreover, the swelling bentonite material deeply penetrates into small fissures and shrinkage cracks. This material combination ensures that the concrete structure is highly water impermeable and thus a flawless operation of the wastewater treatment plant.

Modern solution for stringent building regulations

The wastewater treatment plant is conceived for maximal efficiency and optimum energy consumption. Special control and automation systems are included in order to adjust these consumptions exactly. In addition to that, the treated water will be used for maintenance and cleaning purposes, hence conserving natural resources.

Owing to the location of the plant at the Imperial Island in the middle of the Vltava River, it is moreover essential to protect the plant against flooding. During the „flood of the century“ in 2002, the present wastewater treatment plant was completely inundated and wastewater treatment was not ensured for some time. Surrounding dam walls and a continuous drainage system shall prevent such catastrophes in the future.

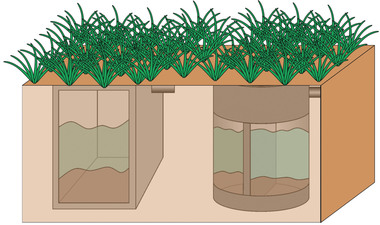

So as not to disturb the cityscape by the wastewater treatment plant, it will be built completely beneath the ground and a park will be created above the ground – a unique project throughout Europe.