Industrial-scale carbon capture project launched

07.02.2018

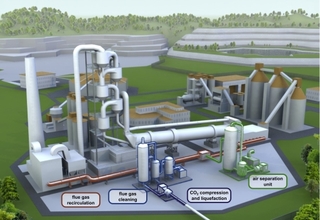

Oxyfuel technology (Figure: ECRA)

Oxyfuel technology (Figure: ECRA)

The cement industry has initiated a demonstration project to test a new breakthrough technology for the future of carbon capture. Based on extensive research undertaken by the European Cement Research Academy (ECRA), oxyfuel technology will now be implemented in two cement plants in Europe. HeidelbergCement and LafargeHolcim will dedicate plants in Colleferro, Italy, and Retznei, Austria, respectively to test for the first time how the cement production process can be adapted to accommodate this cutting edge carbon capture technology. The project will require a significant investment volume and will rely on industry contributions, but significant funding from public sources will also be required.

ECRA’s long-term carbon capture research project was started in 2007 and has advanced to the stage where definite steps towards establishing an oxyfuel kiln can now be taken. Such kilns are intended to provide insight into the industrial-scale operation of a technology, which provides a high CO2 concentration exhaust gas stream for further carbon capture. It is even planned to process a small part of the CO2 to test its further utilization. “The technical feasibility of oxyfuel technology can only be proven in real-scale application, but we have sufficient information from our research to believe that we will obtain a positive result after the trials” said Daniel Gauthier, Chairman of ECRA.

Investment of around 80 million euros

ECRA’s members are leading cement producers, relevant equipment suppliers and cement associations. Through their involvement the project can now be taken further. Based on opportunity studies and in-depth technical feasibility studies, the investment and costs for the test phase will amount to around 80 million euros. While the cement industry has committed itself to contributing 25 million euros, it is clear that substantial funding from European or national research schemes will also be required.

The European Cement Research Academy (ECRA) was founded in 2003 as a platform on which the European cement industry supports, organizes and undertakes research activities within the context of the production of cement and its application in concrete. ECRA regards itself as part of a network, which comprises various research facilities such as universities, federal institutes, and the research centers of cement companies or equipment suppliers. The Academy is steered by a Technical Advisory Board staffed with representatives from major European cement producers.

CONTACT

European Cement Research Academy GmbH

Tannenstraße 2

40476 Düsseldorf/Germany

+49 211 239838-0