New welding machine technology concept at Wire

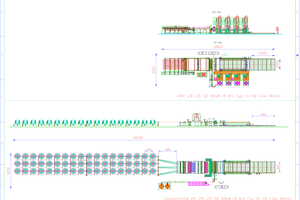

Eurobend GmbH is presenting during Wire Düsseldorf 2024 in Hall 17, Stand A60 a machine from the new AKK R series, which produces mats 2.5m x 6m with up to 49 line wires and wire spacing 50x50mm from coil.

The AKK series sets new standards in the production of reinforcement and industrial mesh such as fence mesh, precision mesh, gabions, double bar mesh and others. The Avant-Garde concept eliminates all changeover times and increases the productivity significantly compared to conventional welding machines: the AKK has no downtimes when changing coils and setting the mesh parameters. On machines with one coil per line wire, each coil change costs time. This downtime adds up considerably. The AKK is designed to avoid exactly this. While one coil per line and cross wire is working, the other coil is in stand-by position and can continue working as soon as the first coil is finished. This system of redundant line and cross wire unwinding stations with single coil wire feed makes the inflexible long coil rows of conventional welding machines superfluous.

High production rates possible

The innovative design of the AKK machines enables automatic changes of the mesh parameters making it the only flexible mesh welding system from coil for high production rates. All mesh types can be produced immediately and without changeovers.

No changeover times for:

Coil change;

Change of longitudinal and cross wire spacing;

Change of mesh dimensions.

In addition, the patented wire feeding system enables a diameter change in a fraction of the time required for this task with conventional mesh welding machines. This makes the machine ideal for „JIT“ (just-in-time) production and efficient product changeovers.

The world wide patented „Automatic Wire Orientation System“ AWOS enables the use of a high-speed roller straightening unit for the longitudinal wires, compensating any wire straightening inaccuracies and guaranteeing the production of flat meshes. The flexibility of the AKK welding systems eliminates the need to stockpile large quantities of finished mesh as is the case when producing with the usual systems.

The AKK machines have a compact system layout with minimal space requirements and are available for processing line and cross wires from coils of up to 8mm, 10mm and 12mm.

“We look forward to welcoming you at Wire Düsseldorf 2024 in Hall 17, Stand A60 and presenting Eurobend‘s innovative technology,“ comments Harris Athanassopoulos, Central and Eastern Europe Operations Manager at Eurobend.

CONTACT

Eurobend GmbH

Alexanderstr. 1

90547 Stein-Nuremberg/Germany

+49 911 9498980