Concrete processing with precision thanks to Pantarhit

The processing of concrete entails some challenges: The material can harden too quickly or its setting can take too long. Processes are slowed down, with idle time occurring, and the product can have quality defects, in case of doubt, even becomes unusable. As a well-established company with profound know-how in concrete chemistry, Ha-Be is well aware of these challenges and has developed pinpointed solutions: The new Pantarhit PC83X superplasticizer series.

Pantarhit PC83X allows fine-tuning in processing

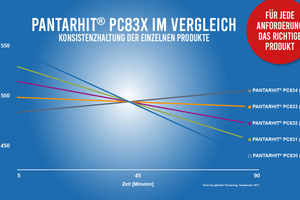

The new series of Pantarhit PC83X superplasticizers comprises the products PC830, PC832, PC833 and PC834, with each being designed for maintaining a specific, pinpointed consistency of the concrete according to different requirements. Depending on the task on hand, ambient temperature and individual work planning, the PC83X series provides users with a kind of modular system for the production of concrete.

If, for example, a longer processing time shall be obtained in case of hot outside temperature, users can choose a product of the series with a higher number. Hence, Pantarhit PC834 (FM) is a superplasticizer that most effectively maintains the consistency, whereas Pantarhit PC830 (FM) provides for the fastest strength development. The classification within the PC83X series allows the user to perform a downright fine-tuning in terms of maintaining the consistency, thus trimming production to maximum efficiency and effectiveness.

Using superplasticizer for an efficient production process

The Pantarhit PC83X products achieve high early strengths in the concrete even in case of low temperatures and without additional heat treatment. Processing cycles can be shortened due to a fast reuse of molds and formwork systems, thus reaching much faster cycle times. Apart from saving of costs and increased efficiency, early strength contributes to a better energy balance and higher sustainability.

Not least, production factories achieve an improvement of the product quality thanks to Pantarhit PC83X. Concrete is compacted perfectly with the aid of the innovative superplasticizer technology. This allows the production of concretes with a closed, low-porous surface and homogeneous appearance, with not only a positive effect on the visiual appearance, but also increasing the quality and durability of the building material.