CO2-optimized precast elements – ecology, economy,

performance and durability

Successive reduction of CO2 emissions in production of precast elements is a central challenge for many manufacturers of precast elements and other concrete products. The means available in this effort are varied and include both technological concrete measures, production engineering as well as planning approaches. It generally applies that technological concrete optimization and the design and detailing of concrete building elements should ideally be considered together for achieving maximum reduction of greenhouse gas and resources.

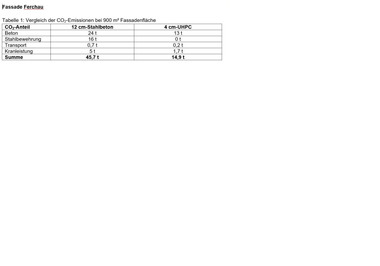

For two chosen precast elements, prestressed concrete girders and angular retaining wall elements, an investigation of systematic measures for climate-optimized production were considered both on technological concrete and component specific levels. This study considered how the individual measures – e.g., use of innovative composite cements or UHPC as well as substitution of steel bar reinforcement with fibers – affect the eco-balance, performance and durability as well as the economic efficiency of the precast elements manufactured. The investigations especially revealed that angular retaining walls made with UHPC can be manufactured noticeably more slender and thus more resource-efficient. With the prestressed concrete girders on the other hand, a reduction in cross section enabled by the higher loadbearing capacity of UHPC is not effective as the sole measure for reducing the greenhouse gas potential. Appreciable greenhouse gas savings were possible only with interlinked measures – both on a technological concrete and structural design level.

In summary, it can be concluded that the use of UHPC both in prestressed concrete girders and especially in angular retaining wall elements can lead to resource reduction and more sustainable precast elements. In addition the study also showed that there is considerable need for further research toward reduction of the resulting greenhouse gas emission of UHPC.